Midlothian

LafargeHolcim is a “Conscientious Corporate Citizen” Everywhere But Texas

In Europe, LafargeHolcim is a multinational cement manufacturer based in Switzerland and France – two countries on the cutting edge of climate crisis planning and members of the progressive European Union. The Company portrays itself as a climate-conscientious corporate citizen, to the point of its Swiss CEO declaring the reduction of CO2 emissions as his first, most important priority.

In Midlothian Texas, LafargeHolcim runs the most conventionally dirty cement plant in Texas and is seeking a permit that could make it one of the most climate-hostile one as well. In fact, there’s some reason to believe the Holcim plant in North Texas is preparing to burn by-products from either the Canadian Tar Sands, the Permian Oil Field, or both, as fuel.

Baking rock to make cement takes a lot of heat. Regardless of how new or old a cement kiln is, regardless of the pollution controls a kiln has, every cement maker in the world still has to employ the same age-old process of applying a 2000 degree open flame to a mix of limestone and other ingredients. A third or more of the cost of running a cement plant is keeping that open flame consistently hot enough to do the job.

This is the reason cement kilns will always try to find cheap, free, even profitable sources of fuel for that flame. Hazardous and industrial wastes that c an be diverted from incinerators or landfills can be burned in cement kilns for slightly less money because they don’t have to meet the same standards. Used tires and oil. Lottery tickets. Dashboards from cars. Even municipal waste is now being burned in kilns.

an be diverted from incinerators or landfills can be burned in cement kilns for slightly less money because they don’t have to meet the same standards. Used tires and oil. Lottery tickets. Dashboards from cars. Even municipal waste is now being burned in kilns.

Burning anything causes air pollution. Burning wastes causes lots of conventional and exotic air pollution, including CO2. But just baking limestone rock also releases a lot of stored CO2. Even if there was some was to make cement without a flame, the heat needed would still release tons of CO2.

Worldwide the cement industry is estimated to be responsible for 5 to 7% of the planet’s CO2 emissions – larger then the airline industry. If the industry were a country, it would be the third largest emitter on earth, behind the United States and China.

Companies like LafargeHolcim are facing both public and financial pressures to reduce that number. In July European funds managing $2 trillion in assets called on cement companies to slash their greenhouse gas emissions, warning that a failure to do so could put their business models at risk. The mangers specifically mentioned LafargeHolcim and urged it to adopt the goal of net zero carbon emissions by 2050 and align itself with the Paris Climate Accords.

LaFarge Holcim has responded by initiating a series of technical innovations and pilot projects under the banner of “The Plant of Tomorrow” to prove its forward thinking.

Almost 300 facilities around the globe are targeted for inclusion in one or more of these “Plant of Tomorrow” projects, including a Canadian kiln installing a carbon-capture pilot project, an Ohio kiln building three wind turbines to secure its electrical needs, and kilns burning industrial waste as “low carbon” (if not low toxic) fuel.

Left out of this mix so far is Holcim’s woe-be-gone Midlothian plant. You might call it Holcim’s “Plant of Yesterday.” Despite having lots of stiff competition, Holcim not only operates the dirtiest cement plant out of the three doing business in Midlothian, but it’s the dirtiest in the entire state.

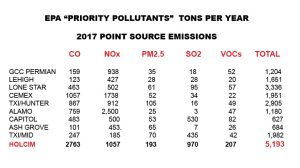

Holcim’s Midlothian plant is the largest Carbon Monoxide (CO) polluter among all 10 Texas cement plants – a sign of poor combustion. It’s the second largest Nitrogen Oxide (NOx) polluter among the bunch, emitting almost twice as much smog pollution as the other two Midlothian cement plants combined. It’s the largest PM 2.5 (Particulate Matter) polluter by far – almost 100 tons a year separate it from second place. It’s the largest Sulfur Dioxide (SO2) polluter by a large margin and releases four times as much Volatile Organic Compounds (VOCs) than the next highest plant. Almost all 2017 pollution numbers for Holcim have gone up over the last five years. A plant that was already bad is getting worse.

Now add Holcim’s request for a new permit to burn 100% Petroleum Coke in one of its two kilns.

Pet Coke is a byproduct of oil refining. It’s a concentrated carbon solid residue that is left behind after the refining process has converted the bulk of the oil into liquid fuels such as gasoline and diesel.

Pet Coke is like coal, but dirtier. Pet Coke looks and acts like coal, but it has even higher carbon emissions than coal. On a per-unit of energy basis Pet Coke emits 5 to 10 percent more carbon dioxide than coal. A ton of Pet Coke yields on average 53.6 percent more co2 than a ton of coal.

As well as significantly higher co2 emissions, Pet Coke also has high sulfur and toxic metals content than coal.

Because its a waste product, Pet Coke is cheap for Holcim to buy or it could even be free if a refinery wanted to get rid of its supply. And now, thanks to the exploitation of the Tar Sands and the oil boom in the Permian the US has lots and lots of Pet Coke. The heavy oil refining capacity in America is now the largest in the world, with over 40 percent of the global market. Much of that production takes place on the Texas Gulf Coast in huge new expanded refinery complexes like Motiva and Total in Port Arthur. The capacity to produce Pet Coke in U.S. refineries has doubled since 1999. In fact, the annual production of Pet Coke is so large these days, it’s outstripped most of the usual uses for it and is “priced to move.”

Because Holcim wants to burn 100% Pet Coke, and it must have a reliable source to burn it 24/7, there’s reason to believe the company has signed a sweetheart deal with one or more refineries to supply it. Probably from the Gulf Coast, and probably from one of the refineries dealing in Canadian Tar Sands oil or Permian Basin product. Both are poster boys for irresponsible fossil fuel development with the Tar Sands and the Keystone Pipeline igniting modern Climate Crisis activism and the Permian becoming one the planet’s largest sources of Methane as tons of unused natural gas are burned off from thousands of rigs.

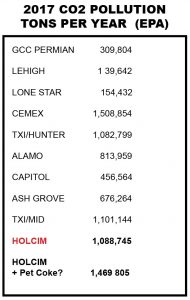

Currently, Holcim is “only” the third largest CO2 polluter among all ten cement plants in Texas, and fourth among all of Holcim’s U.S. plants. But burning 100% Pet Coke in its Kiln #2 could change that rapidly by adding a whopping 400,000 tons more of CO2 to its annual totals. That would send it to #2 in Texas and #2 in the entire US Holcim fleet of cement plants. Not very climate conscientious. And probably not a number you want to tout in trying to sell your “Plant of Tomorrow.”

Currently, Holcim is “only” the third largest CO2 polluter among all ten cement plants in Texas, and fourth among all of Holcim’s U.S. plants. But burning 100% Pet Coke in its Kiln #2 could change that rapidly by adding a whopping 400,000 tons more of CO2 to its annual totals. That would send it to #2 in Texas and #2 in the entire US Holcim fleet of cement plants. Not very climate conscientious. And probably not a number you want to tout in trying to sell your “Plant of Tomorrow.”

At the same time Holcim is trying to project an image of a concerned 21st Century corporate entity to the rest of the world, it’s doing business in Texas like its still 1999.

Officially, the State of Texas doesn’t care about CO2 pollution. Heck, officially it doesn’t even believe there’s a climate crisis. There is no regulatory system for controlling its releases and only the EPA bothers to track CO2 releases at all. So this increase in planet-melting pollution will go completely unaddressed in the permit proceedings themselves.

Also officially, despite the evidence, the State and Holcim both say no other kinds of pollution will increase when 100% Pet Coke is burned at Holcim. No increase in PM 2. 5. No increase in SO2. No increase in metals. Citizens don’t believe them. A group calling itself “Midlothian Breathes” has formed to fight the new permit and has already caught regulators off guard asking tough questions about new emissions.

But trying to get the State of Texas to do the right thing about air pollution is an uphill fight. Instead, perhaps citizens should take these embarrassing numbers directly to LafargeHolcim, who’s claims of new fund corporate responsibility are belied by them. Contrasting its Texas operations with those of the rest of its facilities may be a way to shame the company in its own European backyard. Officially the company may still be able to be embarrassed. Texas state government left that possibility behind years ago.

Mysterious Catastrophic Air Pollution Episode is Why DFW Needs its Own Air Sensor Network

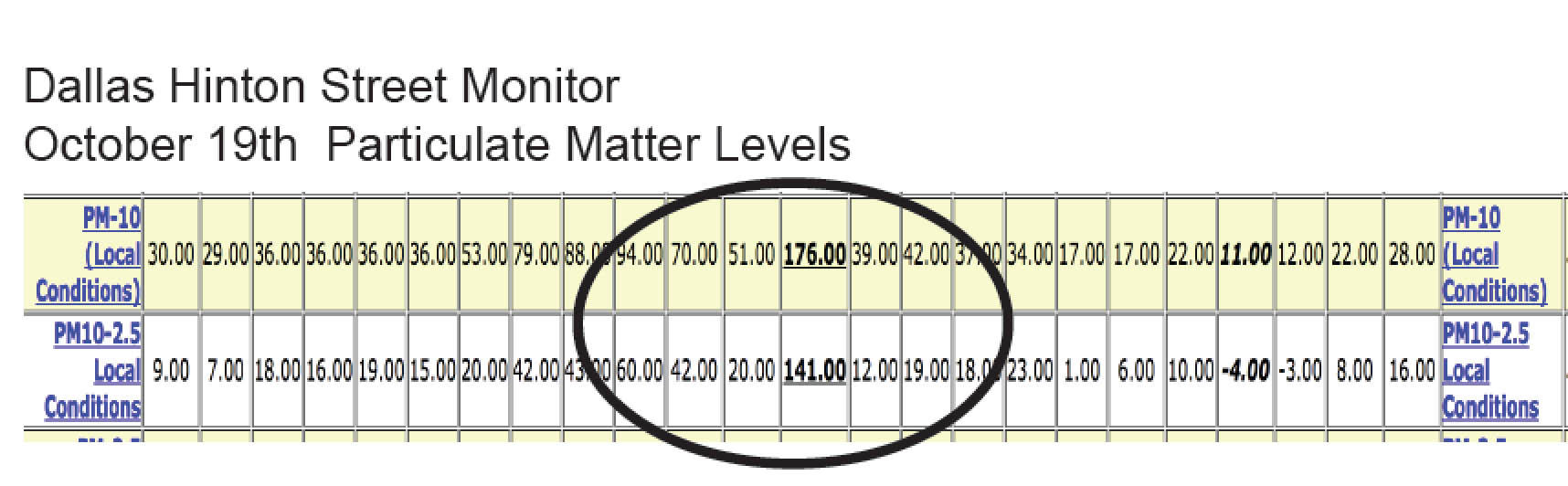

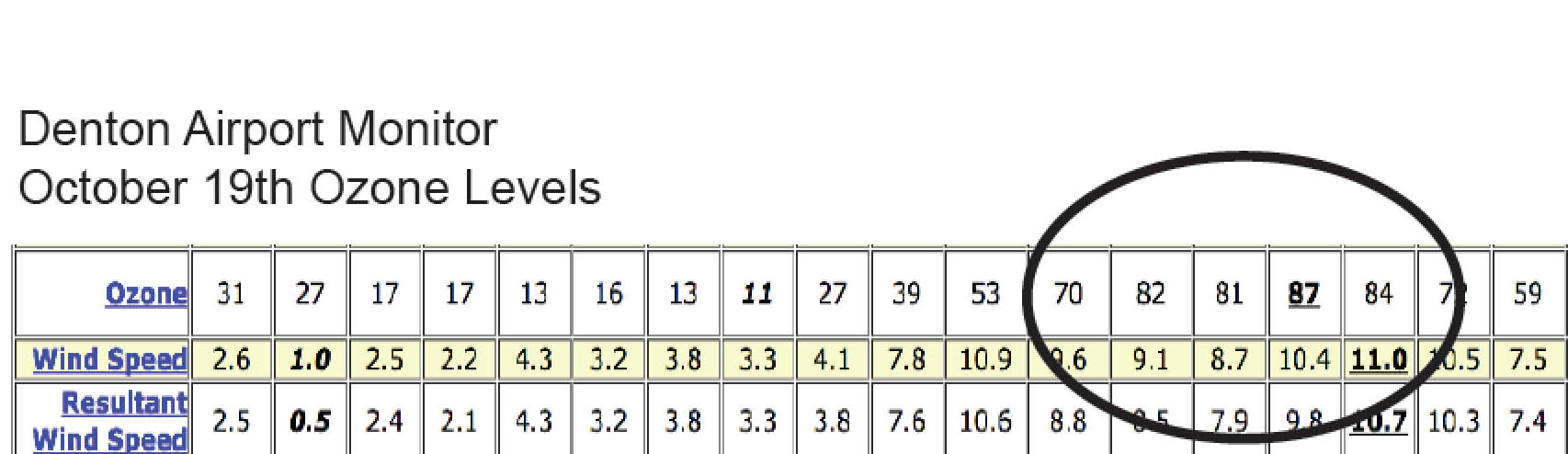

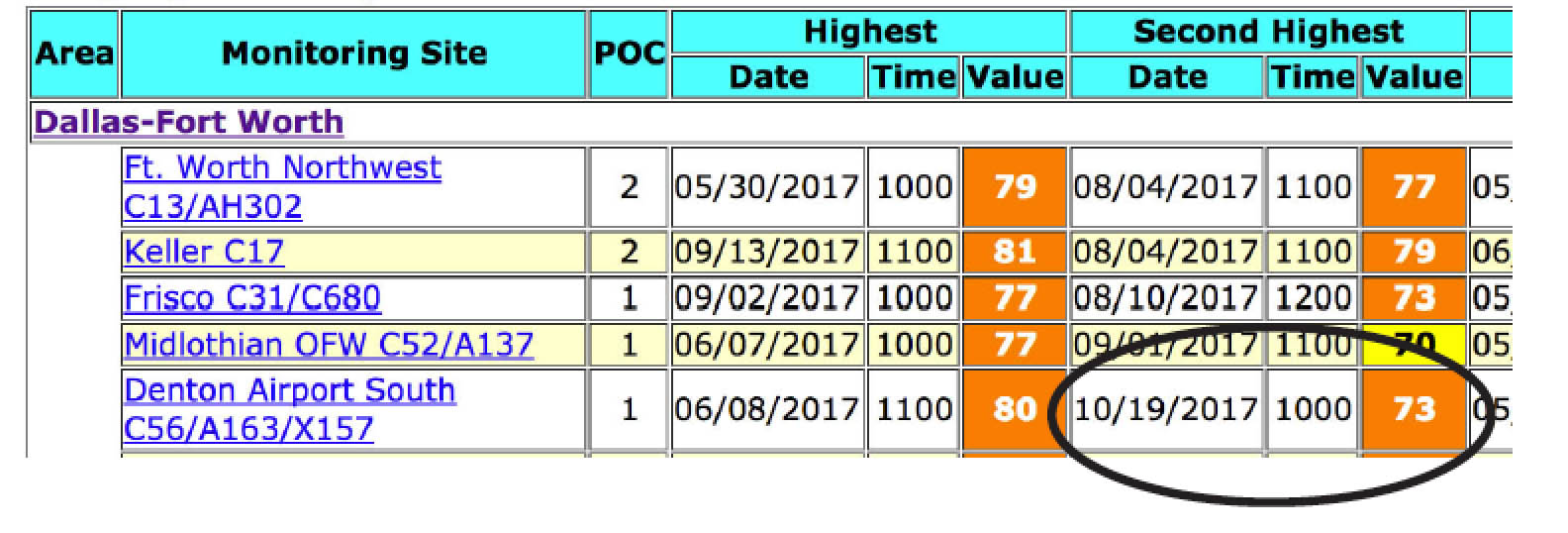

Not quite two weeks ago, on Thursday October 19th, something happened to throw local air quality conditions into the red zone for most of the day.

There was a inexplicable smokey haze extending along the limestone escarpment from Midlothian to Dallas and then north to Denton, sending Particulate Matter pollution soaring to Beijing levels and ozone readings so high the whole regional average went up a part per billion. Countless downwind residents complained to officials, FaceBooked, and Tweeted about “the smell of burning plastic” enveloping their neighborhoods with the smoke, which was so thick many thought the problem was just down the street.

The 24-hour standard for Particulate Matter Pollution is 150 ug/m3. The annual standard is 12.

The 24-hour standard for Particulate Matter Pollution is 150 ug/m3. The annual standard is 12.

70 ppb is the new ozone standard.

The events took the Texas Commission on Environmental Quality completely by surprise. Commission computer forecasting had not predicted an Ozone Alert Day or warned of heavy PM pollution. Officials were playing catch-up for the rest of the day.

Now almost two weeks later nobody official knows what caused this Really Bad Air Day. Not the EPA. Not the Texas Commission on Environmental Quality. Not the DFW area citizens who breathed in the dirtiest air their lungs have seen all year.

Despite the sophisticated technology available to us in 2017, a single unexpected incident upwind of DFW can throw the entire North Texas air shed into the danger zone with no warning and no clue as to what initiated it.

Readings from state monitors were of no help until damage had already been done. As usual they were two hours or more behind in reporting. The numbers they were displaying at 12 noon were actually taken at 10 am. You had no idea what was going on in real time so that you might better protect yourself or family.

There are only three or four Particulate Matter pollution monitors in all of DFW. Even if you’d wanted to use the state’s current monitoring system to track this mystery plume, you couldn’t have done so. It doesn’t have that capability.

As inquiring reporters called, the TCEQ staff found a variety of things to blame. TCEQ suggested the smoke was from a Bastrop forest fire near Austin. But readings from monitors between Bastrop/Austin and Dallas show there was no problem south of Midlothian that day, while there was a huge problem north of there at the same time. Eyewitnesses who saw the plume on Thursday reported a thick narrow ribbon of a plume you’d see coming off a near-by source, not the sort of diffused cloud you’d expect to witness after traveling more than a hundred miles downwind. And then there’s that “burned-plastic smell.”

Then it was maybe one or more “controlled burns” in the Midlothian-Mansfield area. As it turns out, neither fire department found evidence of any permitted controlled burns in their own jurisdictions that could have cause so much pollution. Midlothian’s single permitted fire for the day was “the size of a coffee table” according to a department employee.

According to the Mansfield Fire Department “a fire” was reported to be located at Kimball Road and Hwy 287 just north of the Midlothian city limits. This is what’s at that intersection:

Please note the caution against open flames. Could a fracking site have produced the kind of particulate matter pollution and haze we saw on October 19th without methane or other kinds of pollution being released en masse as well? It doesn’t seem like it could. But what if the fracking site had been turned into a temporary waste incineration site for the day?

That’s not all. A satellite pic of the intersection and what’s around it reveals Kimball and Hwy 287 to be a kind of rogue’s gallery of potential suspects:

Besides the fracking sites you can be see in mid-drilling on this Google street level tour, the road leads to a Trinity River Authority Wastewater Treatment plant and the back door of the giant Ash Grove cement plant.

TRA is a shadowy, 60-year old regional bureaucracy that owns millions of acres of land, reservoirs, landfills, and wastewater-treatment facilities. It’s been in environmental hot water before. Wastewater treatment accumulates a lot of solids, and the TRA handles a lot of trash. It’s not inconceivable that it had something to do with the October 19th incident by thinking it could get away with an open burn on its own property.

Ditto for Ash Grove. Like the other two cement plants in Midlothian, Ash Grove’s kiln is allowed to burn industrial waste, including used oil, tires and plastics – remember the oft-cited “smell of burning plastic” citizens reported on the 19th? Waste-burning cement plants have had their wastes combust and cause huge fires before and each plant has its own emergency response crew which might be able to put out a fire without calling Midlothian.

There’s no proof Ash Grove, TRA or the fracking sites were the cause of the October 19th public health disaster. But there’s also no proof yet they didn’t cause the problem.

The truth is: there’s no official explanation for what made the air so dangerous to breathe on October 19th .

More truth: As of Friday, October 27th the TECQ had not even opened an official investigation into this matter – which again, sent Particulate Matter pollution to levels not seen outside SE Asia and single-handedly raised the regional ozone level.

This is why Downwinders at Risk filed the first of what we’re sure will be a series of Texas Open Record Act requests last Friday seeking:

“Any and all printed or electronic documents and electronic media containing information concerning or related to ozone, particulate matter and/or haze air pollution readings and levels in the Dallas-Forth Worth non-attainment area on Thursday, October 19th 2017, including official ozone action warnings issued, complaints filed about air quality in the Dallas-Fort Worth area that day, photographs, satellite images, computer modeling, as well as all material related to any questions, inquiries, or investigations about air quality in DFW on October 19th anyone in the TCEQ, or contracted by TCEQ has been tasked to perform since October 19th or is still performing currently, and e-mails, letters, reports, telephone logs and notes, memos and all other material about October 19th air quality from 6 am Tuesday October 19th to Wednesday October 25th, 2017.”

TCEQ has until November 10th to respond. We’ll keep you posted.

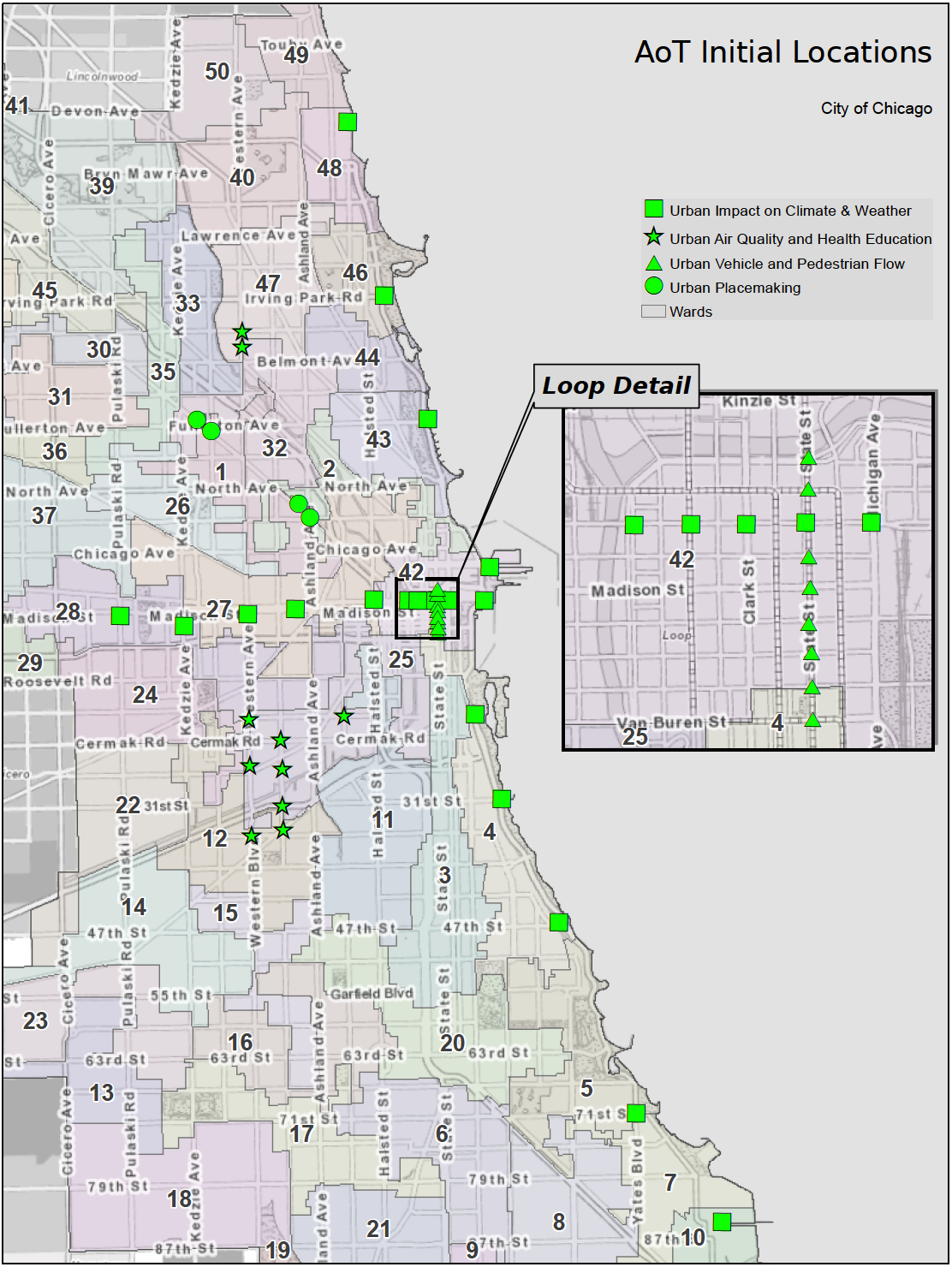

In the meantime, this episode becomes Exhibit A in why DFW needs to catch-up with other metro areas and build its own network of high tech air quality sensors.

If such a grid had been in place, there would have been a real time warning of the PM and ozone pollution being generated shortly after the it started. There would have been a way to locate the source of the pollution right away and do something about it before it got worse, and there would have been a way to predict the plume’s course and warn those in its path before it got there – not two hours after it arrived.

In this sense a modern sensor grid is actually a pollution prevention device, an investigative tool, and an early warning system all rolled into one.

In a metropolitan area that’s been out of compliance with the Clean air Act for 27 years and counting over 14 million lungs are being held hostage by a state air quality monitoring system left over from the 1990’s. It’s being maintained by a state agency that’s run by polluters, officially thinks smog isn’t bad for you, and is cutting its air monitoring budget.

There’s no desire in Austin to update this obsolete system and no money to do so. If DFW officials want to utilize 21st Century technology to help them clean their air, they’re going to have to build their own network of air monitors – exactly the proposal the DFW Air Research Consortium was trying to get funded with a National Science Foundation grant. Close, but no cigar.

There’s no desire in Austin to update this obsolete system and no money to do so. If DFW officials want to utilize 21st Century technology to help them clean their air, they’re going to have to build their own network of air monitors – exactly the proposal the DFW Air Research Consortium was trying to get funded with a National Science Foundation grant. Close, but no cigar.

Without the NSF grant, local officials are going to need to get creative. Are there private businesses who might want to sponsor an app that could tell give you useful air quality info in exchange for naming rights: “Brought to you by the Nissan Leaf DFW Clean Air Network.” Are there local foundations that would contribute? What about local high-tech billionaire Mark Cuban? For less than a million bucks, DFW could have 500 Particulate Matter sensors that would be capable of of pinpointing a problem down to the street address.

Baltimore, Chicago, Chattanooga, Louisville, L.A. , Oakland, and Lafayette, Louisiana are all way ahead of DFW in building out their own local dense grid of air sensors. They’ve done it with a combination of private, government and academic know-how and financing.

We have as much, or more technical expertise and money than any of those locales and we should have more incentive given our chronic air pollution problem. There’s no reason we can’t build our own modern, more protective, more useful way of monitoring air pollution – even if the state isn’t interested. Not only can we do it, but in light of the events of October 19th, it should be considered a necessary act of public health self-defense.

HEFTY! HEFTY! HEFTY! is TOXIC! TOXIC! TOXIC!

Anti-Litter Group “Keep America Beautiful” Teams-Up with Dow and Hefty to Burn Plastic Bags Full of Plastic Garbage in Cement Kilns

And They Want To Do It Here…

We’ve been warning you for a while that garbage burning was coming to North Texas one way or another.

What we didn’t anticipate was that “Keep America Beautiful” would bring it.

That’s right. The same group that gave you Oscar “Iron Eyes” Cody crying over litter is now prepared to make your own eyes water and sting from the air pollution it wants to encourage by burning municipal solid waste, especially “hard-to-recycle” plastics.

Touting bright orange “energy bags” as a quick and easy alternative to throwing those plastics away, a news release issued by the Keep America Beautiful folks, your friends at Dow Chemical, and Reynolds, the makers of “Hefty” trash bags, claims they’re “a convenient way to collect plastic materials that would otherwise end up in the landfill and offers a platform to promote positive behaviors to prevent this material from being wasted.”

What they don’t tout as much is their alternative to throwing these plastics into a landfill – throwing them into a furnace.

As long as cement kilns need a high-temperature flame to make their product, they have large energy costs. Typically, 30% or more of the costs of running a cement plant is in buying the flammable materials necessary to keep that flame lit.

History has taught us that cement kiln operators will burn anything, including the kitchen sink, if they think it will help reduce those high fuel costs.

History has taught us that cement kiln operators will burn anything, including the kitchen sink, if they think it will help reduce those high fuel costs.

Kiln flames in Texas used to be powered by natural gas exclusively. Then it was coal. Then it was hazardous waste and coal. Then industrial wastes. And now municipal solid wastes. In bright orange plastic bags.

Cement plants don’t have to pay for the wastes, now termed “fuel,” for regulatory loophole purposes. In fact, because it’s now a “fuel,” they often get the waste for free or even get paid to burn it. It becomes a new center of profit in the company besides making cement. Maybe even more important. In the 1990’s, there were plenty of rumors about how the TXI cement plant in Midlothian would burn a lot of hazardous waste they got paid a handsome fee to take, but not have much cement product to show for it.

While garbage burning cement kilns have been on the rise in the developing world, the practice hasn’t caught on in the U.S.

Dow’s and Keep America Beautiful’s friendly neighborhood “Energy bags” are a way to jump start it.

This is already happening in Omaha, where 8,500 homes have filled 13,000 “Hefty Energy Bags” since the program’s launch in October. That’s resulted in more than 13,000 pounds of plastics being burned in a near-by Ash Grove cement kiln. They’re so excited about burning plastics at Keep America Beautiful that they’re not only endorsing the practice, they want to bring it to a cement kiln near you.

At a news conference to announce the offering of cash money grants to local communities who wanted to try the option, they unveiled a contiguous states map of the US where they’d like to see the “energy bag” concept implemented. The approximately 50 locations on the map identified by a red (not orange?) star are almost all sites adjacent to large cement plants – including Midlothian, immediately south of the Dallas and Tarrant Counties line, and home of the largest concentration of cement manufacturing in the nation.

Local candidates for eager participation in the project include TXI, the cement plant that burned hazardous waste by the thousands of tons from 1987 to 2008, Holcim, which has sought permits to burn carpet scraps and shingles, and Ash Grove, the same operator as the one burning Omaha’s plastic bags now.

BURNING PLASTIC IS BAD FOR PUBLIC HEALTH AND PUBLIC POLICY

1. It replaces real recycling with burning.

Once you have a hungry garbage burner, you have to keep feeding it with more and more garbage, decreasing the market for real recycling.

This is already happening with tires. There are good tire recycling programs that can’t stay afloat because local governments have promised the local cement kilns a certain volume every year.

2. It gives an incentive to the plastics industry keep to just making plastics that you can’t recycle.

Burning plastic garbage is like a relief valve on the growing piles of “hard to recycle” plastics that industry is producing. Just throw it in a bag and send it to the kiln. Out of sight, out of mind. There’s no question it reduces the percentage of plastics going to landfill…only to increase the percentage of plastic going into your lungs.

The real answer is to reduce and quit producing those “hard-to-recycle” plastics, not giving them a cheap way to get out of doing so.

3. Burning plastic produces lots of toxic air pollution – and all of DFW is downwind of Midlothian

Burning plastics produces toxic air pollution, a percentage of which escapes the smokestack and ends up in the air you breathe, the soil in your garden, and the food you eat and drink. Specifically, burning plastic creates lots of Dioxins and Furans – the same ingredients that made Agent Orange so toxic. The same poisons that made the State of Missouri evacuate the town of Times Beach in 1983.

Burning plastic also releases metals into the air, like cadmium and lead.

Other chemicals released while burning plastics include benzo(a)pyrene (BAP) and polyaromatic hydrocarbons (PAHs), which have both been shown to cause cancer. If plastic film or containers are contaminated with pesticides or other harmful substances, those will also be released into the air. If plastics are burned with other materials, whole new toxic chemicals may be created from the interaction of the different substances.

But wait! Don’t you want to divert more garbage from going to landfills?

Yes you do, but by eliminating, reducing and recycling the garbage – not taking a match to it.

Landfills are nasty things. They’re big and smelly and they leak. Sometimes they leak and contaminate ground and surface water. But these days you usually can trace the plume of those leaks and contain them before they get in drinking water.

On the other hand, once a piece of dioxin-contaminated soot is shot through a smokestack into the atmosphere, you have no idea where it’s going. You’re turning the whole sky into a landfill, full of solid and gaseous residues of refuse. What you didn’t want to drink, you’re now breathing. That’s the opposite of progress.

Taking a look at the Board of Directors for Keep America Beautiful, it’s no wonder they have a soft spot in their heart for large plastics manufacturers. They have not one, but two members from DOW, who, we are sure, thought this was a splendid idea.

Howard Ungerleider is Vice Chairman and Chief Financial Officer of Dow, and Greg Jozwiak is the Business President for the Elastomers and Electrical and Telecommunications businesses for the company. Prior to assuming his current role, he served as North America Commercial Vice President for the Packaging & Specialty Plastics business. Hmmmm.

But wait, there’s more! KAB has a board guaranteed to offend just about everyone. Not content with two Dow executives, it also has two Nestle Corporation members, a representative of Waste Management Inc., McDonalds, Keurig, Anheuser-Busch, and Phillip Morris – yes, that Phillip Morris.

“PEOPLE START POLLUTION. PEOPLE CAN STOP IT.”

Those are the words, spoken in a deep baritone by William “Cannon” Conrad, that ended that famous 1971 Keep America Beautiful commercial in honor of Earth Day. They ring as true now as then.

And so, people, we’re asking you to take action to discourage this kind of BAD IDEA from ever coming-up at a Keep America Beautiful board meeting again – send an email to their new Chair, Helen Lowman.

Ms. Lowman is a former FEMA and Peace Corps executive in the Obama Administration. She’s from Texas, worked at TCEQ, and graduated from Austin College…. So maybe messages from her fellow Texans will have more of an impact.

TAKE ACTION:

TELL KEEP AMERICA BEAUTIFUL’s NEW CHAIR YOU DON’T WANT TO BREATHE TOXIC AIR POLLUTION FORM BURNING PLASTICS

SEND AN EMAIL WITH JUST TWO CLICKS

And if you want to leave a public message for the group too, here’s the group’s FaceBook site.

Other citizens groups, including some national alliances and networks are gearing up to take on this latest proof that all wastes, no matter how toxic, roll downhill to cement kilns eventually.

Meanwhile, Downwinders is taking the lead and beginning the push back we hope buries this project in the bright orange trash heap of history. Join us in not just saying “No,” but “Hell No.” Send that email now and then find two other people that will do the same. Thanks.

We Did It: After 15-Years of Persistent Organizing, Citizens Finally See Modern Controls on a Midlothian Cement Plant. And Now We Want It on All of Them

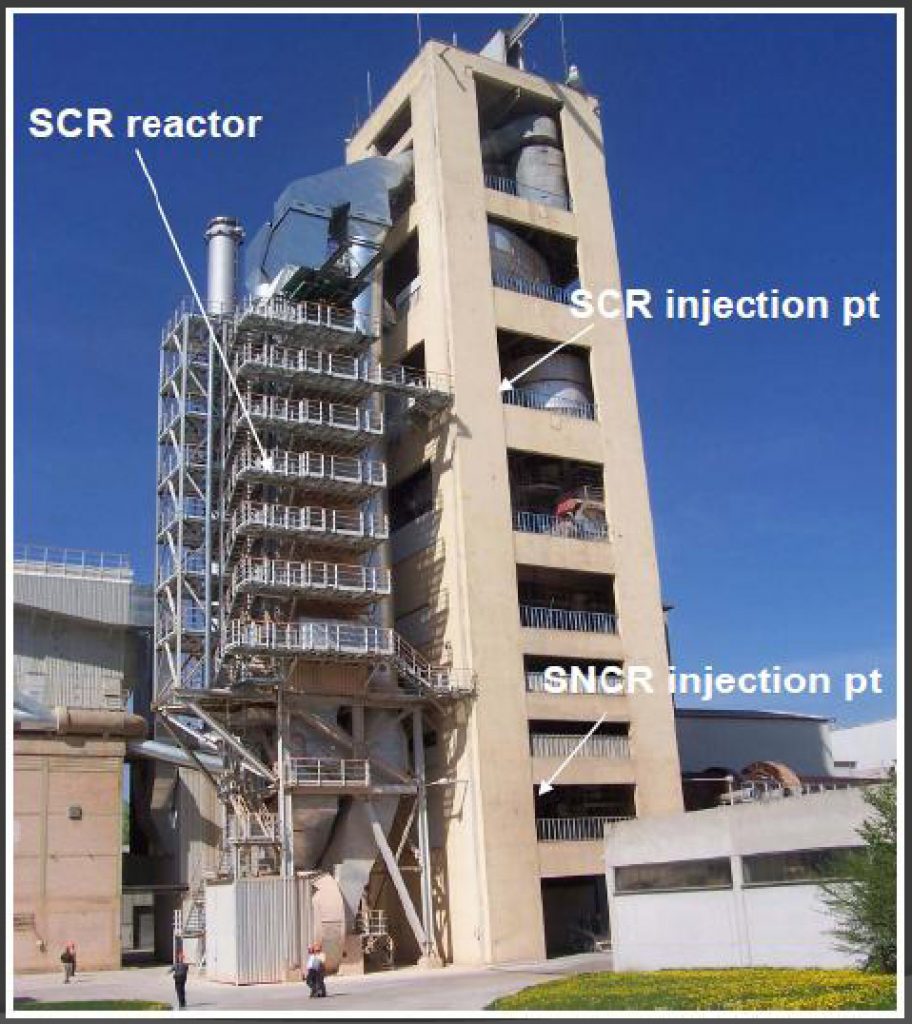

Holcim is the first cement plant in the nation to voluntarily install an industrial catalytic converter called SCR on its smokestack, significantly cutting smog-forming air pollution in DFW.

Holcim is the first cement plant in the nation to voluntarily install an industrial catalytic converter called SCR on its smokestack, significantly cutting smog-forming air pollution in DFW.

But despite operating only 26 miles from EPA headquarters, the Agency and State of Texas still claim the technology isn't "feasible"

Downwinders is proud to announce Midlothian's Holcim cement plant is the first in the nation to voluntarily install pollution control equipment significantly cutting smog-forming air pollution, along with other dangerous emissions.

"Not many people may notice, but Friday is a big day for air breathers in DFW, as well as for everyone in the country who lives downwind of a cement plant," said Tamera Bounds, Chair of Downwinders at Risk, the clean air group that's been relentless in its pursuit of the technology for North Texas since 2001.

Friday marks the official deadline for Holcim's Midlothian cement plant to have its Selective Catalytic Reduction, or SCR system, up and running on one of its two giant kilns in order to be compliant with EPA emissions limits.

Although almost a dozen cement plants in Europe have installed the technology over the last twenty years and it's widespread in the American coal industry, Holcim is so far the only cement plant in the U.S. to install SCR on one of its kilns without a government mandate.

A pilot test using SCR at Midwest cement plant was required by a Department of Justice enforcement action in 2010. Results show smog-forming pollution was cut by at least 80% – roughly twice as much as pollution controls now in use in the US, including Midlothian. In Europe, SCR has a track record of removing 80-90% or more of the smog-forming pollution that has kept DFW in violation of the Clean Air Act since 1991. It also cuts the emissions of air toxics, particulate matter, and dioxins by double-digits.

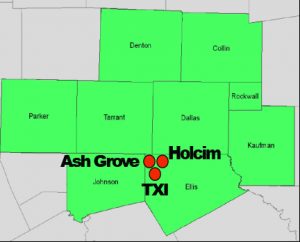

With three cement plants and four kilns, Midlothian hosts the largest concentration of cement manufacturing in the US, and the largest "stationary" sources of air pollution in DFW. Since the late 1980's, the city has become a national battleground over cement plant pollution. First, over the use of hazardous waste as "fuel" for the local kilns, then over the closing of dirtier, obsolete "wet" kilns contributing to smog and climate change, and now over how fast new kilns can be updated to reflect 21st technology.

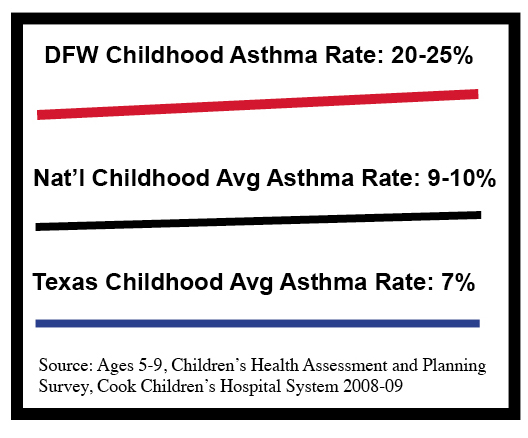

Bounds and others say the installation of SCR on all four kilns in Midlothian would mean a huge benefit to public health for residents in Tarrant County, where the predominant winds push the plumes from the kilns. A 2009 Cook Children's Hospital study showed childhood asthma levels highest directly downwind of the cement kilns.

The demand for the technology is a central part of the group's push to replace the current State-sponsored anti-smog plan with a more effective, and protective, one from EPA. So far, Dallas County, the City of Dallas, two Congressional Representatives and a State Legislator agree with them. But incredibly, the Agency maintains the SCR technology Holcim has freely invested in to reduce pollution and is already operating less than 30 miles from its regional headquarters is not "technically feasible."

Downwinders and other groups in the DFW Clean Air Network regional alliance are challenging EPA's refusal to recognize a game-changing pollution control technology that could help DFW finally put its smog problems behind it a well as offering similar help to other parts of the country downwind of cement plants.

"It's rare these days to find the EPA embracing Texas' approach to ignoring advances in environmental science, but that's exactly what happening," said Bounds. "Both State and EPA officials are acting like 3rd Graders – closing their eyes and humming loudly, pretending this time-tested technology isn't operating right in front of them. But it does, and it's here to stay."

Bounds wants the EPA to take note of the cuts in pollution triggered by Holcim's operation of its SCR system and then hold ALL the Midlothian plants to the same modern standard. "You have a piece of equipment that is setting a higher bar for pollution control. Every cement kiln in DFW should have to meet that higher bar now. No other anti-pollution strategy makes sense."

It's been a long and circuitous route to getting SCR installed in a Midlothian cement kiln. Along the way, the region's clean air activists moved the entire nation closer to widespread use of this control technology.

North Texans first heard about the use of SCR in the cement industry through a citizens group fighting a proposed new cement plant in New York state in 2001.They'd commissioned a study from a NYC engineering firm identifying European cement plants that had already successfully installed the technology.

Downwinders tried and failed to include SCR in the anti-smog plan in 2003. It then used a 2005 settlement agreement with the State over the failure of that plan to get the then Rick Perry-controlled Texas Commission on Environmental Quality to perform an independent assessment of the technology. That landmark study produced results that are still reverberating today. In it, five independent experts chosen by Downwinders, the cement industry, and the State declared SCR to be ready for prime time.

"SCR is a commercially available technology. It offers the possibility of significant NOx reduction at the plants in Ellis County. As an 'add on' technology, which can achieve 90% or greater NOx reduction, with demonstrated performance at hundreds of coal fired power plants, SCR is a viable technology that is available for both dry and wet kilns."

That conclusion, from cement industry experts, in a TCEQ study, is now a decade old.

At the same time they were working to bring SCR to Midlothian, Downwinders also led the fight for new EPA emission limits on cement kilns that burn hazardous waste. A 2009 national hearing at DFW Airport attracted over 200 people. Those emission limits clamped down on air toxics. Holcim couldn't meet them without adding controls. They choose an SCR unit on one kiln and a thermal oxidizer (re: flame) on the other to try and stay in compliance. Even though Holcim installed SCR to address air toxics, or Volatile Organic Compounds and not smog pollution, the effect on emissions will be the same.

Meanwhile, the 2006 TCEQ study and subsequent push by Downwinders for SCR in Midlothian helped persuade the EPA to require the pilot test in 2010. That test, as well as Holcim's experience in Europe, set the stage for SCR's official debut on the Texas prairie on Friday.

"It's been a long fight, but change is hard," said Bounds, "and it doesn't happen in a straight line."

Help Us Celebrate This Victory That Was 15 Years in the Making

Please consider contributing $25 or more on "GIVING DAY" NEXT THURSDAY to keep us on the front lines of change another 15 years.

Giving Day is an all day online giving event sponsored by the Communities Foundation of Texas.

Downwinders will have our own online Giving Day page where you can click and give from 6 am through 12 Midnight next Thursday.

Every contribution of $25 or more is matched or extended by the Foundation.

This year, we need your support to keep our full-time staff in the field, as well as fund our 2nd annual Root and Branch Revue for activists, and assemble our North Texas Clean Air Forceof air-monitoring drones.

Oh yeah, we're also opening a school for organizers in January.

We're based in DFW. All our board members are from DFW. Our priority is DFW air. Your contribution stays in North Texas to fund the fight for clean air in North Texas.

We know you're being assaulted by Giving Day appeals from all the local non-profits, and there are lots and lots of good causes. We only request that you ask yourself how many other local groups can repeatedly pull off meaningful victories with so few resources?

We were able to bring SCR to Midlothian with your help. We need your help again next Thursday. We think we've earned it.

Thanks.

Downwind in Switzerland: “Do you carry responsibly-sourced concrete?”

(Half of these people represent industry. Half are environmentalists. Can't tell which ones? That's a good thing.)

Should a bag of concrete be like an organic banana or a new chair made out of recycled wood and get "certified" as being responsibly-sourced, or "sustainable?" And if so, what's the criteria for making such a judgment, and who's making it?

Those are the complicated questions at the heart of a new worldwide initiative by the concrete/cement industry to come up with a way to sell its products in a more environmentally-friendly way.

After a couple of years of working on a scoring scheme, the mostly European-based intra-company group (LaFarge/Holcim, Heidelburg, CEMEX) charged with designing the system was ready to unveil it to the international environmental community for the first time in mid-July at a small meeting in Gland, Switzerland, headquarters of the International Union for the Conservation of Nature, whose staff facilitated the review process. IUCN had performed the same function for the aluminum industry when it went through a similar "green" self-examination.

Nine different environmental groups from at least seven different countries (Britain, Bulgaria, China, India, Lebanon, Switzerland) spent three days assessing and critiquing the industry's proposal – including the lone representative from the U.S., Downwinders at Risk's Jim Schermbeck. Participants not only met during the day, but ate together, and stayed in the same lone hotel in the small, outlying suburb of Geneva. Inside the meeting room, discussions were often frank, funny, and awkward. Outside, conversations ran the gamut, from architecture, to vacation trips, to Texas BBQ.

It's not a surprise that the concrete/cement business wants its relatively messy business to be seen through green-tinted glasses. Old timers will recall the burning of hazardous waste in Midlothian cement plants was relabeled "recycling" in the 1980's and 90's.

But this time around, the pressure is not necessarily to greenwash the transformation of a cement kiln into a waste incinerator, but to give an environmental patina to the final product, concrete, so that it can compete in the marketplace with building materials that already have their own green certification schemes up and running.

In other words, there appears to be new market pressure on the industry to "go green." Wood and Aluminum all now have their own systems for doing so. Concrete/Cement is lagging behind because it can't point to such a system. They want everyone from a construction site manager to a do-it-yourselfer to ask for "certified concrete" in the same way customers want wood that wasn't cut from a rainforest habitat, and aluminum made with Bauxite that wasn't mined at the expense of indigenous peoples.

Congratulations. Consumer demand for green products is so great that even the conservative cement/concrete industry feels the need to respond.

But that's also not news to North Texans. Certainly one reason Downwinders had a seat at the table in Switzerland was our pioneering Green Cement campaign of 2006-2011 which used government procurement policies to reward less polluting Midlothian cement kilns and punish the dirtier plants. That was the first time the marketplace for cement had been used toward greener ends in the US.

While that local effort looked exclusively at the differences in air pollution impacts from the Midlothian cement kilns, this new initiative starts at the limestone quarry, includes the aggregate industry (sand and gravel) goes through the cement kiln, and then continues all the way to the concrete batch plant and the bag of Sakrete at the store. It looks at impacts to water supply and quality, air quality, energy use, climate change, and local populations at each of these stops along the product cycle.

Much of the energy behind the initiative seems to come from a new generation of European industry representatives who've grown up with a different sensibility that takes green values for granted. More than one environmentalist noted a more open and questioning tone to the back and forth conversations. Whether this new attitude can be sustained and allowed to flow into real policy changes, is of course, the acid test of this first round, which must be finished for a pitch to the CEOs of the major industry players in December. Apparently the bosses are not entirely sold on the idea of needing such a certification at all, and, at times the whole idea had the air of being a kind of end-run around the Establishment by some Young Turks, albeit, corporately-backed.

And there are some very large challenges that could sabotage any good intentions, primarily, the continued reliance on burning wastes for the substantial fuel needs of a cement kiln. As much as kilns have modernized, making cement still involves cooking rock at very high temperatures provided by a very hot, continuous flame. Something has to fuel that flame day after day, year after year. Just buying the fuel for that flame represents as much as 60% of the operating costs of a cement plant.

This is why companies are always looking for ways to cut those energy costs: by turning themselves into incinerators and charging generators to burn their toxic wastes, by getting subsidies from government to burn wastes like tires, by getting refuse from other industries which would otherwise have to pay to have them hauled away. In terms of large PR problems, none loom larger than the inherent one that goes with the introduction of burning wastes in the local kiln. That's how Downwinders got our start.

But because of the volume of fuel needed as well as the required high temperatures, there are only so many kinds of things a kiln can practically burn. Midlothian kilns began by burning natural gas. If you're only looking at the end result of the flame, and not how the gas got here, it's still probably the cleanest source of fuel. Then there's coal, which is a no-go fuel in 2016 for all kinds of reasons. After that you get to wastes. Even if it doesn't have a permit to burn "hazardous" wastes, a kiln still can burn things like carpet pieces, plastics, shingles, and car "fluff." These are all materials that can release toxic air pollution when burned. Finally there's biomass – wood refuse, agricultural waste, or fuel crops themselves like sawgrass. Originally supported universally by environmentalists, these choices now have climate consequences that make them less desirable.

These are not easy choices for industry….or environmentalists. Schermbeck made the offer to industry to sit down and work on an agreed "hierarchy" of wastes that would establish minimum high BTU value and low toxicity levels, as the group had done over a decade ago with TXI in a private mediation process that never panned out, but showed vast differences in fuel characteristics. At last word, the offer was being mulled over by industry along with all the other suggestions made by environmentalists. By October we should know how first round of assessment has changed the scheme – or not. Then another round of feedback from the environmental community, and a final decision by the end of the year.

At stake is the potential to connect environmental progress and profit-making within one of the most environmentally-disruptive industries around. To establish performance floors, raise best practices, set new precedents. There are large risks and opportunities for both sides.

Besides being close to the corporate headquarters of most of the major companies invovled, and home of the IUCN, Switizerland seemed the appropriate place for this first-time gathering for another reason. At the end, everyone arrived at as if on the edge of a metaphorical mountain precipice with a sizable, but not insurmountable gap separating where the industry is now, from where it needed to be. Whether that gap can be bridged any time soon remains to be seen. But the meeting in Gland was a good keystone to put in place for any future span designed for the job.

New Comments from EPA on DFW Air Plan: It Won’t Work

This plan won't work.

This plan won't work.

That's the simple message from the three pages of new comments Region 6 EPA staff submitted to the Texas Commission on Environmental Quality last month concerning its anti-smog plan for DFW.

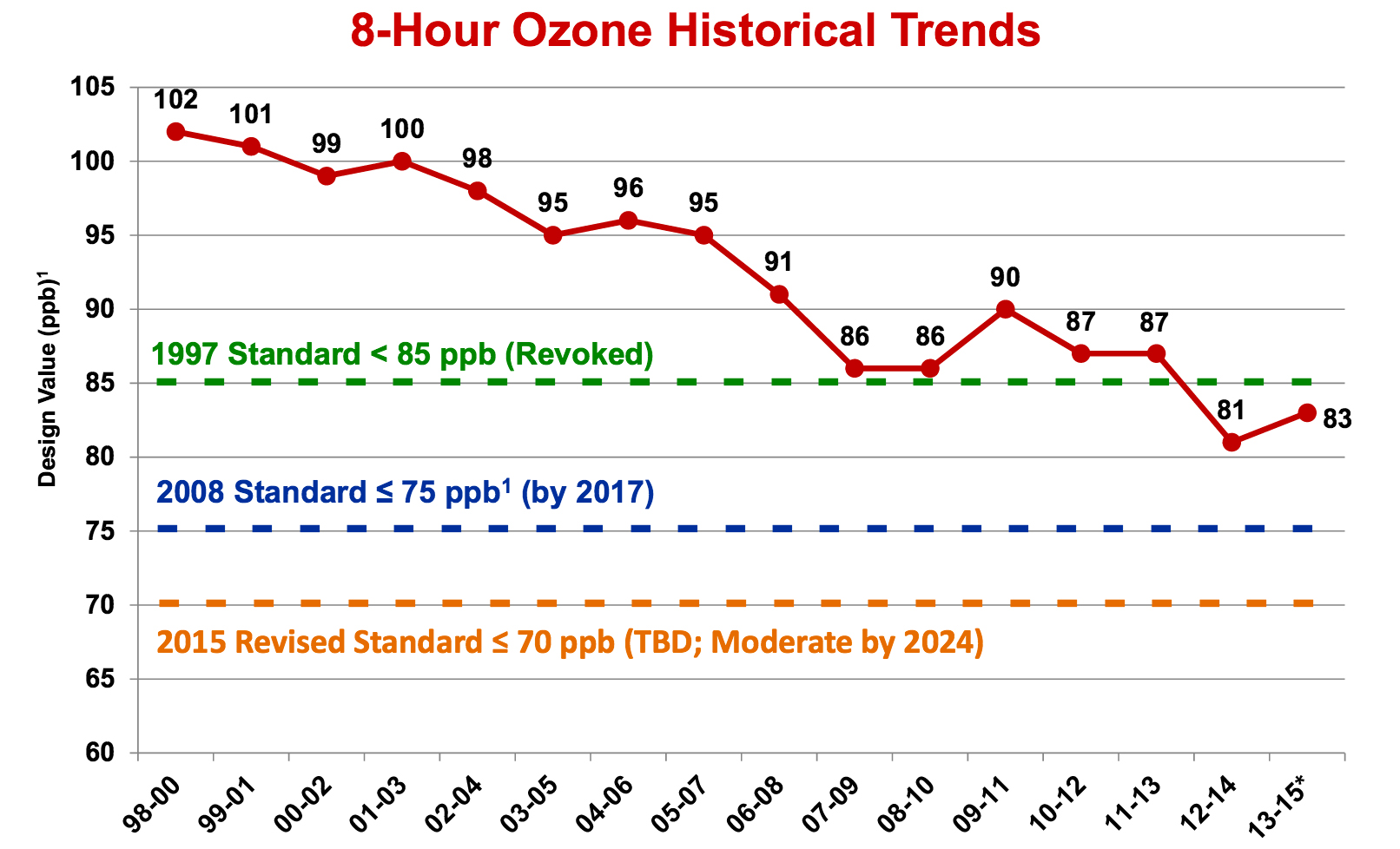

That message begins with the cover letter, written by Mary Stanton, Chief of the State Implementation Plan Section for Region 6. "… additional local and regional ozone precursor emission reductions will be necessary to reach attainment by 2017."

How much in reductions? EPA estimates an additional 100-200 tons per day more in cuts of smog-forming pollution will be necessary to achieve compliance with the current 75 parts per billion ozone standard. "Without emission reductions on this scale, it is unlikely that the area will attain by the attainment date.”

To give you some idea of how large a number that is, TCEQ calculates that all gas and oil air pollution in DFW equals 78 tons per day, the Midlothian cement plants belch out over 18 tons per day, and all the power plants in the immediate DFW area, 21 tons per day. Totaled, those three sources add up to 117 tons of pollution a year.

All the cars and trucks on DFW roads are said to add up to 180 tons per day of pollution.

So the decrease in pollution EPA is saying is necessary to get down to the current ozone standard is huge.

But take a look at those obsolete East Texas coal plants outside the boundaries the DFW nonattainment area. TCEQ says they account for a total of 146 tons per day. Add Selective Catalytic Reduction (SCR) which can get you up to 90% reductions in coal plant emissions, or close them down completely, add decreases from new controls on the cement kilns and oil and gas sources, and you're well on your way to amassing 200 tons a day of cuts in pollution.

Which do you think is more attractive to most DFW residents: permanently parking their cars, or putting new controls on the coal plants? Even though the coal plants harm the whole DFW airshed more than any other major source, they're not held accountable to the same regulatory requirements as sources closer to the center of the urban core, but which have less impact. Our cars must have special gasoline formulas in summer, we have to have HOV lanes, and we still go through Ozone Action Days, but the coal plants party like it's 1979. TCEQ is taking a hands-off approach to the plants and as a result the DFW region will continue to be in violation of the smog standard or huge cuts from other sources will be necessary.

TCEQ could have added new controls to the coal plants to the plan, but it chose not to. In fact, there are no new controls in the state's plan on any major sources of air pollution affecting DFW. EPA's new comments go to the heart of that choice. "Without additional emission reduction measures, we don’t see how the area will meet the standard of 75 ppb by the end of the 2017 ozone season," writes EPA staff.

EPA goes on to say TCEQ's computer modeling supporting it's do-nothing plan is "unrealistic," severely underestimating future smog levels, and delivering projections of decreases "that seem unlikely to be reached."

With this stance, EPA seems poised to reject this "attainment demonstration" part of the air plan as being insufficient. But it must wait to see how TCEQ responds to EPA comments about its modeling shortcomings and need for new cuts when the state officially submits its plan this July. Then, and ony then can the Agency approve or disapprove. We're going out on a limb here and predicting TCEQ won't change a thing, thus inviting EPA disapproval.

With this stance, EPA seems poised to reject this "attainment demonstration" part of the air plan as being insufficient. But it must wait to see how TCEQ responds to EPA comments about its modeling shortcomings and need for new cuts when the state officially submits its plan this July. Then, and ony then can the Agency approve or disapprove. We're going out on a limb here and predicting TCEQ won't change a thing, thus inviting EPA disapproval.

That's the pattern TCEQ has already established with its "screw you" response to the EPA's comments about the part of the plan dealing with "Reasonably Available Control Technology," or RACT, last February. This second part decides what new controls should be required of major sources of air pollution within the 10-County DFW "non-attainment" area – like the Midlothian cement plants and the thousands of oil and gas facilities checkerboarding the western half of the Metromess.

TCEQ says nothing new is required. EPA disagrees. EPA told TCEQ last year it had to do a new RACT review and lower the kiln's emission limits to account for a new generation of technology or it would have to reject the state's plan. TCEQ ignored the request, daring the EPA to disapprove. EPA seems more than willing to take them up on the offer.

And so while you're waiting for the state's computer modeling and suspect math to be rejected by EPA in July, you can probably expect to see EPA officially rejecting the RACT part of the state's plan sooner – maybe as soon as the next 60-90 days.

Despite the TCEQ going out of its way to submit an unacceptable plan to EPA, if the Agency pulls the trigger and begins a federal takeover of the DFW air plan, the Commission and the whole of Texas State Government will cry bloody murder about the usurpation of the state's authority and once again proclaim how "out of control" the EPA is on their way to filing suit.

This is why the rowdy eruption of public sentiment for an EPA plan at the hearing in Arlington two weeks ago was so critical (Thank you again). It's also why we now have to be about the business of getting DFW local governments, hospitals and school districts to pass resolutions in favor of an EPA takeover. The Agency will need this kind of public support to counter all the criticism it will take from the Usual Suspects in Austin and DC. If you're interested in helping us pass one of these resolutions in your county, city, school or hospital district, please let us know at: downwindersatrisk@gmail.com

This is why the rowdy eruption of public sentiment for an EPA plan at the hearing in Arlington two weeks ago was so critical (Thank you again). It's also why we now have to be about the business of getting DFW local governments, hospitals and school districts to pass resolutions in favor of an EPA takeover. The Agency will need this kind of public support to counter all the criticism it will take from the Usual Suspects in Austin and DC. If you're interested in helping us pass one of these resolutions in your county, city, school or hospital district, please let us know at: downwindersatrisk@gmail.com

And as always, it's why you, and people you know should:

Spanish Study: Link Between Cement Kilns and Cancer

Although it was first published last July, news of a new Spanish epidemiological study of residents living in proximity to cement plants has just now reached us.

Although it was first published last July, news of a new Spanish epidemiological study of residents living in proximity to cement plants has just now reached us.

Done by the the same researchers responsible for a 2012 study that found statistically significant increases in all cancers around waste incineration and auto scrap metal operation, this more recent report focuses just on cement, lime and plaster plants.

According to the researchers, a statistically signifiant increase in all cancer mortality was detected in the vicinity of these installations as a whole, but principally, in the vicinity of cement installations. Specifically, tumors of the colon–rectum in both sexes and of the pleura peritoneum, gallbladder, bladder and stomach in men were noticably higher. In a summary of the results, the authors state they believe residents have "an excess risk of dying from cancer, especially in colon–rectum, in towns near these industries."

Because they take such a long time and so much effort, there's a dearth of epidemiological studies focused entirely on cancer risks among those living in proximity to cement plants, although a 2004 Italian study found a significantly greater risk of lung cancer among people living near a cement factory (whereas the results of another Italian study confirmed significant excesses for cancers like the nervous system, leukemia, mesothelioma and peritoneum in a region with the presence of various industries including cement factories.

In explaining the higher incidence of gut cancers among both men and women, the study hypothesizes about the possible ways local residents are exposed to carcinogens:

In our study, one aspect to be borne in mind is that colorectal

cancer is the only tumor with statistically significant excess risks

in men and women, which might be indicative of a pathway of

environmental exposure. In this case, two possible routes of exposure

to the pollution released by these installations are considered:

direct exposure to pollutants released to air; and indirect exposure,

both to pollutants and liquid effluents which are released to water

and can then pass into the soil and aquifers, and pollutants which

are released to air and then settle on plants. In such cases, the toxins

may pass into the trophic chain, affecting the population.Some authors have already shown associations between colorectal cancer and proximity to industrial pollution sources as metal industries (Garcia-Perez et al., 2010), mining (Fernandez-Navarro et al.,2012), food and beverage sector (Lopez-Abente et al., 2012) andchemical plants (Wilkinson et al., 1997). As regards cement plants,

a Brazilian study found a significant elevation on colorectal cancer

mortality in an industrialized area with cement industries came

into operation in the 1960s, among other facilities (Medrado-

Faria et al., 2001), and a Korean occupational study suggested a

potential association between exposure in the cement industry

and an increased risk of rectal cancer (Koh et al., 2013).

One thing a lot of these overseas studies and the Midlothian area have in common is a concentration of heavy industry. There's usually more than one facility and the region is considered an industrial corridor. That's certainly true of Midlothian, where besides hosting three large cement plants, the town is also home to a huge secondary steel mill, a power plant, and now an LNG plant. These industries combine to present a multitude of possible synergestic combinations of toxins to anyone living adjacent to, or downwind of them. "Toxic soup" is a term often used to describe the result.

This is also why the law lags behind the science in setting standards for cause and effect. When it's the cascade of chemicals from various facilities assaulting you, you're rarely going to be able to link a particular disease or illness with a specific plant. And yet the harm is happening all the same. This is why institutionalizing the "Precautionary Principle" into public policy is so important. It's much easier to prevent a chemical exposure than to track all of its ill effects after it's already doing damage.

Downwinders and Sierra Club File Joint Comments on the State’s DFW “Do Nothing”Air Plan

Wednesday of last week saw the deadline for filing official comments on the dreadful "plan" the Texas Commission on Environmental Quality has proposed to lower smog levels in DFW by 2018. In effect, the plan is to wait for federal gasoline changes in 2017 and hope for the best.

Wednesday of last week saw the deadline for filing official comments on the dreadful "plan" the Texas Commission on Environmental Quality has proposed to lower smog levels in DFW by 2018. In effect, the plan is to wait for federal gasoline changes in 2017 and hope for the best.

Shortly before closing time Wednesday, Downwinders at Risk and the Lone Star Chapter of the Sierra Club submitted 62 pages of criticisms concerning the plan. Not because either organization believes the TCEQ Commissioners will change heir minds, but because we're trying to establish a record that might eventually lead to a court challenge of the plan.

Although lengthy, the basic approach of the groups is two fold – call into question the state's computer modeling that's predicting success and challenge the state's exclusion of new pollution control measures on the Midlothian cement plants, East Texas Coal plants and Barnett Shale gas compressors.

Some of the highlights:

– The computer modeling the TCEQ is using for its new plan is the same it used for plans in 2006 and 2011, neither one of them successful at meeting its goal of cleaner air by the assigned deadline. In fact, the last clean air plan using this same model underestimated smog levels by almost 10 parts ber billion and actually saw a slight rise in smog at its conclusion – the first time a DFW plan ever resulted in higher ozone levels.

– In defiance of EPA guidance, the computer model TCEQ is using is more than five years old. EPA specifically recommends using an "ozone season" from 2009 to 2013. TCEQ's model is leftover from 2006, or three years older than the oldest year EPA says is appropriate.

– Also contrary to EPA rules, the TCEQ 2006 computer model ignores including the most relevant “meteorological conditions conducive to elevated air quality.” 2011 was the worst year for ozone levels in DFW since the beginning of this decade, in large part because it reflected the worst drought conditions. The three-year rolling average for the worst monitor, called the "design value" rose back up to 90 parts per billion after years of floating in the mid to upper 80's. But instead of using that year as a worst case baseline, the state defaulted to its 2006 model that doesn't incorporate the current drought.

– TCEQ's prediction of success is built on a series of unrealistic assumptions about the quantity of oil and gas pollution. For example, it underestimates the number and impact of air pollution from hundreds of large compressor stations and thousands of smaller "lift" compressors as the Barnett Shale ages. Fully 60 to 70% of all air pollution from the gas industry comes from these kinds fo facilities, so a mistake in estimating their impact could have a large chain reaction at downwind air quality monitoring sites in Tarrant, Denton, Parker and Johnson counties.

TCEQ also assumes that production levels in the Barnett will fall steeply. If they do not, there could be hundreds of tons more air pollution from the industry annually than what TCEQ assumes in its model.

That's important because the model predicts that the region will only barely squeak-by the 75 ppb standard required by 2018, with levels coming in at 75.87 at the Denton monitor site, 75.15 at Eagle Mountain Lake, and 75.04 in Grapevine. A jump in oil and gas pollution – or any other surge in pollution from any other source – could make those numbers obsolete and ruin our chances fo complying with the Clean Air Act on time…again.

– TCEQ's "Contingency Measures" are illegal. Every smog plan must have a series of quantifiable back-up contingency pans in case the options the plan relies on fail to achieve success. In this case, the state is only relying on unquantified and voluntary actions, such as "incentive" programs, the effectiveness of which cannot be measured. Since you can't measure them, you can't count them.

– TCEQ failed to consider all "reasonably available control technologies" and "measures." Nearly 40 pages is devoted to the wrong-headed, irrational, and illegal way TCEQ rejects off-the-shelf air pollution controls for the Midlothian cement plants, East Texas coal plants, and large gas compressors.

Under the Clean Air Act, a state's plan “shall provide for the implementation of all reasonably available control measures as expeditiously as practicable (including such reductions in emissions from existing sources in the area as may be obtained through the adoption, at a minimum, of reasonably available control technology) and shall provide for attainment of the national primary ambient air quality standards.” In order for the EPA to determine whether an area has provided for implementation as "expeditiously as practicable,” the State "must explain why the selected implementation schedule is the earliest schedule based on the specific circumstances of that area. Such claims cannot be general claims that more time is needed but rather should be specifically grounded in evidence of economic or technologic infeasibility.”

Step-by-step, Downwinders and the Sierra Club explains why Selective Catalytic Reduction (SCR) is a reasonable control technology for the Midlothian cement plants and East Texas coal plants. Even as the owners of one of the Midlothian cement plants applies for a permit to install the technology, TCEQ is claiming its still not ready for prime time. The groups demonstrate how requiring SCR on these major polluters would have a large impact on DFW ozone levels.

The same level of absurdity if reveled in TCEQ's rejection of electrification of gas compressors. Despite being able to significantly lower smog-pollution in the very areas where its needed most, and despite electrification even being required by many Barnett shale municipalities, the state maintains that this option is unrealistic and unachievable.

There's probably no better compendium of the various sins committed by the TCEQ plan than these comments. If you're looking for the most solid case for compressor electrification, or SCR adaptation, or just TCEQ malfeasance, this is your one-stop shop.

You may think this is a technical document, or one full of legal mumbo-jumbo. It's not, at least not for the most part. Instead it's the kind of logical, evidenced case you'd assemble for a debate with the TCEQ. It's a blow-by-blow comprehensive look at why the state isn't any more likely to meet this clean air deadline than it has any other. A case we hope is capable of persuading EPA to reject the TCEQ plan.

Why DFW Residents Should Speak in Favor of a Lower Smog Standard at Thursday’s EPA Public Hearing in Arlington

All Day NATIONAL Public Hearing on a New Federal Ozone Standard

Thursday, January 29th, 9am to 7:30 pm

Arlington City Hall, 101 W. Abram

There are only three national public hearings on the possibility of lowering the national federal ozone, or smog, standard. One is in Washington DC, another is in Sacramento, California and the third is right here in Arlington, Texas. We need everyone that can come and speak for 5 minutes on the importance of cleaner air to do so. You know industry and elected officials hostile to the EPA and the Clean AIr Act will be well-represented

To secure your 5-minute speaking slot, e-mail Eloise Shepard and ask for one in the time period during the day on Thursday most convenient for you. Please do it asap: shepherd.eloise@epa.gov.

There are at least two very good reasons why North Texas residents should support a new lower smog standard of 60 parts per billion – the lowest standard under consideration by the EPA.

1. DFW has Epidemic Childhood Asthma Rates

1. DFW has Epidemic Childhood Asthma Rates

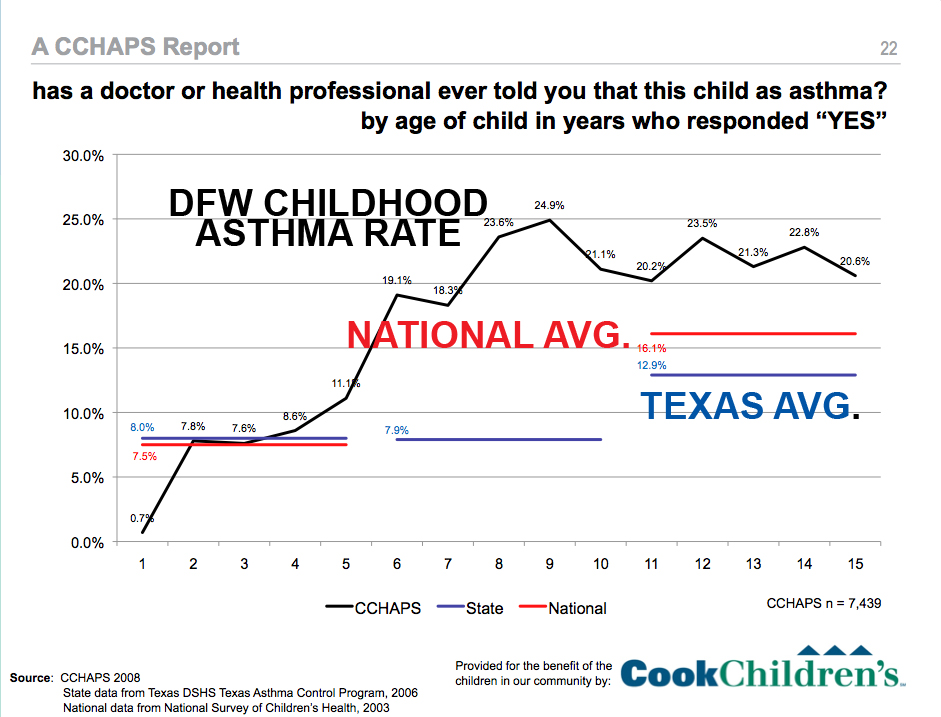

According to a first-of-its kind survey in 2008 by Cook Children’s Hospital, one out of every four DFW children ages 5-9 suffered from asthma. That was more than twice the national average, and more than three times the average for the state of Texas. Asthma is the most common cause of missed school days and is one of most common causes of Emergency Room visits and hospitalizations.

The DFW Hospital Council estimates nearly 1500 children in Dallas County visited an emergency room or were admitted to a hospital due to asthma in 2012. Dallas County has the highest number of child asthma hospitalization in the state.

According to EPA itself, a new 60 parts per billion (ppb) standard for ozone would eliminate roughly 1.8 million asthma attacks, 1.9 million missed school days, and 6,400 premature deaths nationwide – 95% of all ozone-related deaths. Few regions would benefit more from such a lower ozone standard than DFW.

2. It’s One of the Few Ways to Force Reductions in Harmful Air Pollution in Texas

Texas is a place where industry rides rough shod over state regulators and citizens don’t have a level playing field to seek relief from the adverse health consequences of air pollution. Tougher federal ozone standards are one of the only ways to reduce air pollution from large local sources like the cement kilns in Midlothian, gas facilities in the Barnett Shale, and coal plants in East Texas.

Lower federal ozone standards over the last two decades, combined with grassroots campaigns have resulted in the lower volumes of smog pollution from the Midlothian cement kilns, plus reductions in other kinds of harmful pollution from the kilns as well, like particulate matter, and carcinogens. A new 60 ppb ozone standard would mean the kilns would have to add state-of-the-art controls to bring down those totals even more – to as much as 90% reductions. The same is true with the East Texas coal plants and with polluting gas facilities. To get down to 60 ppb ozone levels in DFW could mean deep cuts from the largest sources of industrial air pollution in North Texas. Something that probably won’t happen without a new, lower federal ozone standard.

And that won't happen without a lot of you showing up on Thursday to say you want and need cleaner air to breathe. Reserve your 5-minute speaking slot now. It's a good investment if you live in Texas.

Don’t put away those gas masks yet: EPA’s National Ozone Public Hearing is Next Thursday in Arlington

All Day NATIONAL Public Hearing on a New Federal Ozone Standard

Thursday, January 29th, 9am to 7:30 pm

Arlington City Hall, 101 W. Abram

(To secure a 3-minute speaking slot, e-mail Eloise Shepard and ask for one in the time period most convenient for you. Slots are going fast (and not necessarily to citizens), so do it asap: shepherd.eloise@epa.gov)

It's Round Two of January's clean air public hearing marathon, and the biggest has been saved until last.

One of only three national public hearings on lowering the federal ozone, or smog standard, is taking place here in DFW, at Arlington City Hall all day next Thursday January 29th, from 9 am to 7:30 pm.

Last week saw a state-sponsored hearing on another TCEQ do-nothing DFW clean air plan. But the state wouldn't even have to pay lip service to such plans were it not for the requirement to meet a federal ozone level and the region's inability to do so over the last two decades.

Lowering the federal ozone level means it will be tougher in the future for the state to claim it doesn't have to implement any new pollution controls on cement kilns, coal plants, or gas facilities. More importantly, enforcement of a tougher standard means better public health: fewer "bad air days," fewer asthma attacks, fewer trips to the emergency room because your child can't breath, and fewer deaths caused by dirty air.

That's important because reports like the child heath survey from Cook Children's hospital in 2009 showed that childhood asthma rates in DFW were twice the state average and almost 10% higher than the national average. It called the prevalence of asthma among local children an "epidemic."

Currently, the national ozone standard is 75 parts per billion (ppb) – which DFW is still at least three years away from reaching even under the rosiest of scenarios. (Right now our average is 81 ppb, and that's only because of a wetter and cooler summer in 2014). But that 75 ppb number is a political compromise – not one grounded in science. Based on public health studies the EPA's own independent board of specialists has recommended a range of 60 to 70 ppb at least three times since 2008, with an emphasis on the lower end of that range. Now it looks as if the EPA is finally willing to follow through on that recommendation.

EPA's national ozone standard sets the goal of cleaner air that every state must work toward. It drives all new clean air plans. like the one the state of Texas is proposing for DFW right now. The lower the standard, the more pollution has to be reduced. The more pollution has to be reduced, the more controls have to be added to major sources of air pollution to get that reduction. That's how you get long-term clean air progress in states like Texas that refuse to act on their own.

A significant reduction in the federal standard – from 75 (ppb) to as low as 60 ppb would make it much, much harder for Texas to avoid new controls on industry. To give you some idea of how much harder, consider that the state's "plan" for compliance with the current 75 ppb level is completely dependent on a new EPA gasoline mix coming onto the market in 2017. Even then, it's own estimates say that it won't get down below 75 at least three or four monitoring sites. Just one monitor site out of compliance means the whole region is in violation. Short of a huge rise in the use of electric cars, more huge decreases in vehicle pollution aren't expected. Additional significant drops in smog that would be required under a new, lower standard would have to include controls on major industrial sources – like the cement kilns, coal plant and, yes even gas facilities.

When you have a much lower ozone standard, you have to reduce smog by addressing ALL sources of air pollution.

Finding a way to comply with a lower national ozone standard is how more modern pollution controls were mandated almost a decade ago at the Midlothian cement plants. Meeting that new ozone standard meant pollution from the kilns had to be reduced and that made it more possible for Downwinders' "Green Cement" campaign to work with local governments. Today, there are no obsolete "wet kilns" left in Texas – they've all been replaced with more modern dry kiln operations. This has resulted in a reduction of hundreds, even thousands, of tons of smog-forming air pollution from these huge sources every year. We still have to require state-of-the-art Selective Calaytic Reduction (SCR) on the kilns, but they're releasing far less pollution than they were even five years ago because they've had to comply with a new federal ozone level.

With a new, lower ozone standard, the same could be true of new controls on gas facilities, like the 650 large compressors in North Texas, and the East Texas coal plants. That's why it's important for Texas residents to fight for the lowest possible standard this time around. When you testify, please make sure you request a new standard of NOT MORE THAN 60 PARTS PER BILLION.

According to a recent EPA staff analysis, an ozone standard of 60 ppb would reduce asthma deaths in the US by 95%, compared to only a 50% reduction under a 70 ppb level. If you want air that can eliminate all but a small fraction of respiratory problems associated with outdoor pollution, you need to press for a 60 ppb standard.

Needless to say industry is fighting back hard against such a standard, using its usual doom and gloom forecasts of economic hardship. This is the same argument that was used against the current ozone standard – the one we have now in the middle of the biggest economic boom in a decade. In fact, the technology for bringing down pollution levels currently exists in many industries – including kilns, coal plants and compressors. It's not experimental and it's not too expensive to use, as demonstrated by its use right now in those industries. We just have to require its use in states like Texas that are refusing to implement progress. That's why this new standard is so important – it will make the state take action it would not otherwise take. It's one of the only ways citizens who care about cleaner air in Texas can force progress.

Likewise, the Texas Commission on Environmental Quality's own toxicologist, Michael "Smog Ain't Bad For You" Honeycutt will also be testifying. TCEQ knows that a lower standard will force its hand on new controls. It will be pulling out all the stops to use its influence and that of sympathetic elected officials to scuttle any change. Using ideologically-based arguments supported by industry-financed studies, the TCEQ will say there are no real benefits to reducing DFW smog. Those of you that know better have to show up and say so.

Speaking slots for the 29th are going very fast. Industry will be well-represented. Please don't get left out. We need your voice that day to call for a 60 ppb national ozone standard. E-mail the EPA at shepherd.eloise@epa.gov and reserve your time today.