Hazardous Waste

Downwind in Switzerland: “Do you carry responsibly-sourced concrete?”

(Half of these people represent industry. Half are environmentalists. Can't tell which ones? That's a good thing.)

Should a bag of concrete be like an organic banana or a new chair made out of recycled wood and get "certified" as being responsibly-sourced, or "sustainable?" And if so, what's the criteria for making such a judgment, and who's making it?

Those are the complicated questions at the heart of a new worldwide initiative by the concrete/cement industry to come up with a way to sell its products in a more environmentally-friendly way.

After a couple of years of working on a scoring scheme, the mostly European-based intra-company group (LaFarge/Holcim, Heidelburg, CEMEX) charged with designing the system was ready to unveil it to the international environmental community for the first time in mid-July at a small meeting in Gland, Switzerland, headquarters of the International Union for the Conservation of Nature, whose staff facilitated the review process. IUCN had performed the same function for the aluminum industry when it went through a similar "green" self-examination.

Nine different environmental groups from at least seven different countries (Britain, Bulgaria, China, India, Lebanon, Switzerland) spent three days assessing and critiquing the industry's proposal – including the lone representative from the U.S., Downwinders at Risk's Jim Schermbeck. Participants not only met during the day, but ate together, and stayed in the same lone hotel in the small, outlying suburb of Geneva. Inside the meeting room, discussions were often frank, funny, and awkward. Outside, conversations ran the gamut, from architecture, to vacation trips, to Texas BBQ.

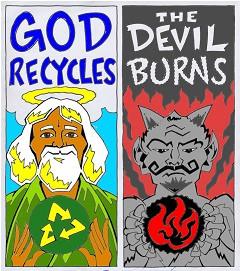

It's not a surprise that the concrete/cement business wants its relatively messy business to be seen through green-tinted glasses. Old timers will recall the burning of hazardous waste in Midlothian cement plants was relabeled "recycling" in the 1980's and 90's.

But this time around, the pressure is not necessarily to greenwash the transformation of a cement kiln into a waste incinerator, but to give an environmental patina to the final product, concrete, so that it can compete in the marketplace with building materials that already have their own green certification schemes up and running.

In other words, there appears to be new market pressure on the industry to "go green." Wood and Aluminum all now have their own systems for doing so. Concrete/Cement is lagging behind because it can't point to such a system. They want everyone from a construction site manager to a do-it-yourselfer to ask for "certified concrete" in the same way customers want wood that wasn't cut from a rainforest habitat, and aluminum made with Bauxite that wasn't mined at the expense of indigenous peoples.

Congratulations. Consumer demand for green products is so great that even the conservative cement/concrete industry feels the need to respond.

But that's also not news to North Texans. Certainly one reason Downwinders had a seat at the table in Switzerland was our pioneering Green Cement campaign of 2006-2011 which used government procurement policies to reward less polluting Midlothian cement kilns and punish the dirtier plants. That was the first time the marketplace for cement had been used toward greener ends in the US.

While that local effort looked exclusively at the differences in air pollution impacts from the Midlothian cement kilns, this new initiative starts at the limestone quarry, includes the aggregate industry (sand and gravel) goes through the cement kiln, and then continues all the way to the concrete batch plant and the bag of Sakrete at the store. It looks at impacts to water supply and quality, air quality, energy use, climate change, and local populations at each of these stops along the product cycle.

Much of the energy behind the initiative seems to come from a new generation of European industry representatives who've grown up with a different sensibility that takes green values for granted. More than one environmentalist noted a more open and questioning tone to the back and forth conversations. Whether this new attitude can be sustained and allowed to flow into real policy changes, is of course, the acid test of this first round, which must be finished for a pitch to the CEOs of the major industry players in December. Apparently the bosses are not entirely sold on the idea of needing such a certification at all, and, at times the whole idea had the air of being a kind of end-run around the Establishment by some Young Turks, albeit, corporately-backed.

And there are some very large challenges that could sabotage any good intentions, primarily, the continued reliance on burning wastes for the substantial fuel needs of a cement kiln. As much as kilns have modernized, making cement still involves cooking rock at very high temperatures provided by a very hot, continuous flame. Something has to fuel that flame day after day, year after year. Just buying the fuel for that flame represents as much as 60% of the operating costs of a cement plant.

This is why companies are always looking for ways to cut those energy costs: by turning themselves into incinerators and charging generators to burn their toxic wastes, by getting subsidies from government to burn wastes like tires, by getting refuse from other industries which would otherwise have to pay to have them hauled away. In terms of large PR problems, none loom larger than the inherent one that goes with the introduction of burning wastes in the local kiln. That's how Downwinders got our start.

But because of the volume of fuel needed as well as the required high temperatures, there are only so many kinds of things a kiln can practically burn. Midlothian kilns began by burning natural gas. If you're only looking at the end result of the flame, and not how the gas got here, it's still probably the cleanest source of fuel. Then there's coal, which is a no-go fuel in 2016 for all kinds of reasons. After that you get to wastes. Even if it doesn't have a permit to burn "hazardous" wastes, a kiln still can burn things like carpet pieces, plastics, shingles, and car "fluff." These are all materials that can release toxic air pollution when burned. Finally there's biomass – wood refuse, agricultural waste, or fuel crops themselves like sawgrass. Originally supported universally by environmentalists, these choices now have climate consequences that make them less desirable.

These are not easy choices for industry….or environmentalists. Schermbeck made the offer to industry to sit down and work on an agreed "hierarchy" of wastes that would establish minimum high BTU value and low toxicity levels, as the group had done over a decade ago with TXI in a private mediation process that never panned out, but showed vast differences in fuel characteristics. At last word, the offer was being mulled over by industry along with all the other suggestions made by environmentalists. By October we should know how first round of assessment has changed the scheme – or not. Then another round of feedback from the environmental community, and a final decision by the end of the year.

At stake is the potential to connect environmental progress and profit-making within one of the most environmentally-disruptive industries around. To establish performance floors, raise best practices, set new precedents. There are large risks and opportunities for both sides.

Besides being close to the corporate headquarters of most of the major companies invovled, and home of the IUCN, Switizerland seemed the appropriate place for this first-time gathering for another reason. At the end, everyone arrived at as if on the edge of a metaphorical mountain precipice with a sizable, but not insurmountable gap separating where the industry is now, from where it needed to be. Whether that gap can be bridged any time soon remains to be seen. But the meeting in Gland was a good keystone to put in place for any future span designed for the job.

Have You Seen This Bucket of Hazardous Waste ?

It's 2014. Distant parts of the globe are connected within micro seconds. Some of us are driving electric cars. Our phones are more powerful than all the computers it ever took to put a human being on the Moon, combined.

It's 2014. Distant parts of the globe are connected within micro seconds. Some of us are driving electric cars. Our phones are more powerful than all the computers it ever took to put a human being on the Moon, combined.

And we use five gallon buckets from Academy to collect and store industrial hazardous waste.

Or at least the Exide contractors that are in charge of "cleaning-up" Frisco's Stewart Creek do. And they not only use them, they lose them.

On May 8th, workers for Apex-Titan Inc. were collecting battery casing chips and bits of lead slag from fields near the Creek a the intersection of Legacy and Stonebrook and putting them into the bucket. For decades before it closed in 2012, the Exide lead smelter dumped waste into and around the Creek, leaving a still-contaminated trail from the plant site all the way to Lake Lewisiville, approximately five miles away.

After collecting a full load of Exide waste, the contractors placed the bucket in the back of a pick-up truck and drove off – apparently without securing the tailgate first. Despite two staff from the Texas Commission on Environmental Quality on the scene to "document field activities" and the City of Frisco's own contractor present – nine people in all – no one noticed when or how the bucket fell off the truck on he way back to the plant site.

When they discovered the loss, the workers retraced their route. They searched the parking lot of a city park located across the street from a school – one of two in the immediate vicinity. No bucket. More than two weeks later the bucket of hazardous waste is still missing. But we're only now finding out about it.

This would be funny if it weren't for the possibility of this bucket ending up with kids or in a garden or as a water container. As a memo from the City of Frisco puts it:

"We believe it is a reasonable assumption that the bucket was found in the street by a person who picked it up for their own use; without realizing the contents might be hazardous waste."

With that in mind, did the City of Frisco inform the Frisco School District? Did any warnings get issued to students and parents at the two near-by schools? Not as far as we know. Did the City put out an All Points Bulletin for the bucket? No it did not. Embarrassment often keeps officials from doing the right thing about public health. So there's hazardous lead waste out there in a Frisco neighborhood that could be diminishing kids' IQs even as you're reading this, even as officials are too embarrassed to ring the alarm.

Now maybe you're thinking this whole Frisco lead cleanup fiasco now has a new mascot. And you' be right. This bucket pretty much sums up the FUBAR'd state of things. A bankrupt company entrusted to clean-up its own mess. A city council seemingly intent on making sure it ends up with a Superfund Site in the middle of the "second-fastest growing city in America." A state and federal government asleep at the wheel. It's all nicely summed up by that lost five gallon Academy bucket. That's the image. Here's the caption, however, thanks to Jack Fink at Channel 11:

"Mack Borchardt of the city of Frisco said he’s surprised, since they were assured going into this process by Exide that there wouldn’t be any problems with the system in place. “Obviously, that didn’t turn out to be the case,” said Borchardt."

City officials were shocked! Shocked they tell you, that Exide screwed up.

Frisco City officials handed the job over to Exide and expected the same company that ran an outlaw smelter operation to provide an excellent clean-up of their own mess. They had faith! The City is handing over the toxicology and assessment to the state and EPA. They have faith! They're handing the decision about what to do with the waste in Frisco to their lawyers, who are recommending the city host a toxic waste landfill by Stewart Creek in front of the new Grand Park. They have faith! What they don't have is any faith in their own citizenry. After 2 years there's still no transparent, civic dialog on the fate of the thousands of tons of lead waste that remains in the heart of the central business district.

There's no question that given a choice, most Frisco residents would vote to haul the waste completely out of town to a hazardous waste disposal site and develop the property as any other prime piece of real estate. And yet the Frisco City Council is still on course to approve a permanent toxic landfill of its own…… that would be monitored by the same state agency that didn't see that five gallon bucket falling out of the contractor's truck.

What's needed now more than anything else is homegrown vision and leadership. The city needs to take its fate into its own hands instead of entrusting others to look out for its self-interests. There's millions of dollars in state-collected battery fees that are supposed to be going to communities impacted by lead smelting. Frisco certainly qualifies. Instead of arguing with its own residents over a permanent landfill, the Council should be proposing legislation for the next session in Austin to finance a full clean-up.

This incident is a five-gallon splash in the face. Following instead of leading can only result in many future "problems with the system."

D-I-V-O-R-C-E….Is the Frisco-Exide Settlement On the Rocks?

After a brief honeymoon, is it Splitsville for the 2012 clean-up agreement between Exide and the City of Frisco? And if their shotgun marriage is breaking apart, what are the implications for Frisco residents and the surrounding area, including Lake Lewisville, a source of drinking water for Dallas that sits directly downstream of what now may become a Superfund site?

After a brief honeymoon, is it Splitsville for the 2012 clean-up agreement between Exide and the City of Frisco? And if their shotgun marriage is breaking apart, what are the implications for Frisco residents and the surrounding area, including Lake Lewisville, a source of drinking water for Dallas that sits directly downstream of what now may become a Superfund site?

On February 25th, Channel 11 broke the story that, after almost two years of assuming the settlement would guide clean-up efforts, the City of Frisco doesn't "know if the company will stick with the deal or walk away from it until the company files a reorganization plan by the end of May."

That's a big deal. Having declared bankruptcy last year, Exide is now dealing with thousands of creditors with competing claims. Frisco is only one of them, and only one of a half dozen closed or operating lead smelter sites that are also suffering from contamination. If the City's deal with the company can't survive the bankruptcy process, all the current planning for clean-up and redevelopment of the outer ring of Exide will be derailed. And that's important because the settlement has been the Frisco City Council's justification for not opening up the fate of the property to more public discussion, like whether residents would prefer building a toxic landfill and keeping Exide's waste in town, or cleaning up the entire sire and hauling off all contamination to allow for normal development.

It's also important because without the city's deal in place, and Exide in bankruptcy court, there is no Plan B to prevent the entire site from becoming an EPA federal Superfund site, exactly the same way the still languishing RSR lead smelter site in West Dallas ended up as as Superfund site in the early 1990's after that company went belly up. It's a designation that Frisco officials are known to dread.

There have been signs of trouble with the agreement for months now. According to documents filed by the City of Frisco in federal bankruptcy court last December, Exide is in default on its agreement with the City, and risks further claims of breaches, as well as “fraud in the negotiation, execution, and performance” of the settlement.

The historic 2012 settlement arranged for a swap of 179 acres of Exide-owned land in Frisco in return for $45 million from the Frisco Economic Development Corporation and the Frisco Community Development Corporation. Passed unanimously by the Frisco City Council with only a week’s public notice and no public hearings, the agreement closed the smelter earlier than expected but is based on an elaborate series of conditions and clean-up standards.

It’s at least one of those conditions, the required demolition of “all above-ground structures” in a section of the smelter site the city is purchasing called the “Bowtie Parcel,” which appears to be the center of the default claim by Frisco. Specifically, it’s the continued presence of a specialized building involved in the treatment of the smelter’s wastewater known as “The Crystallizer,” that prompted the legal tension.

Last August, Mack Borchardt, the City’s Special Assistant in charge of monitoring the Exide clean-up, wrote a letter to the company disputing the Agreement’s demolition provision had been fulfilled as long as the Crystallizer remained standing:

“Frisco disagrees with your assessment that the demolition activities on the Bowtie Property have been completed and demand that you retract Exide’s notice immediately. For example, the Master Settlement Agreement requires (A)ll above ground facilities on the Bowtie Parcel…” to be removed from the Bowtie Parcel as part of Demolition Activities.” The above ground facilities include the Crystallizer which has not been removed and it has not been approved in writing by Frisco to remain standing. If you fail to immediately withdraw Exide’s notice, Frisco reserves the right to pursue all available remedies.”

By December 9th, when a Bankruptcy Court deadline required the City to file its claims against Exide, Frisco City Hall was adamant that “Exide has not demolished and removed all above ground facilities…. As a result, Exide is in default on its performance obligations under the Master Settlement Agreement.” But along with that outstanding claim, City lawyers also added a new list of possible Exide violations, both civil and criminal:

“Finally, Frisco may also have additional contract and/or tort based claims against Exide, including,without limitation, breaches of the Master Settlement Agreement, nuisance, quantum meruit, money had and received, breach of fiduciary duty, negligence and gross negligence, conspiracy, and claims based on fraud and fraud in the inducement and/or negligent misrepresentations relating to the negotiation, execution, and performance of the Master Settlement Agreement.”

If the deal between Frisco and Exide comes apart, there’s nothing to guarantee that any of the smelter property gets cleaned-up or redeveloped the way the City’s been promising.

Although the entire Exide smelter site and surrounding property is full of toxic hot spots, the facility at the center of the latest legal dispute, “the Crystallizer,” has been a source of particular regulatory concern. As part of the final processing of contaminated waste water at the smelter, it condensed filtered liquids into sodium sulfate solids.

In a December 2009 report, EPA inspectors at Exide observed, “Uncontrolled salt laden runoff from the Crystallizer plant was observed as salt deposition on the concrete aprons around this process area at the plant. The ‘frac’ tank used for holding purge water from the crystallizer plant was leaking at the time of viewing.” This crystallized substance tested high for toxic metals content and testing of the contents of the frac tank showed toxic levels of selenium and cadmium.

In September 2010 inspectors again found “uncontrolled salt laden runoff from the Crystallizer plant and also that the frac tank was leaking.”

In July of last year the Texas Commission on Environmental Quality reported that “the levels of sulfate in soils surrounding the Crystallizer unit are much higher than in other areas” and “drums of PCBs were noted in the Crystallizer area.” PCBs, or Polychlorinated biphenyls, were once widely used as cooling fluids, but have been banned in the US since 1979 because of their persistent toxicity.

Because of its use of chlorine in treatment of waste, the Crystallizer could also be one of the major reasons Exide became one of Texas’ largest Dioxin polluters. In 2009, the Frisco facility was ranked as the 9th largest source for Dioxin pollution in Texas, surpassing all other North Texas facilities, including the Midlothian cement plants. Dioxin is one of the most potent toxins ever tested by EPA, and is measured in grams, not pounds.

Despite this history, no testing for Dioxin contamination has ever taken place at the former Exide smelter site by any regulatory agency, and that’s a point of contention for critics of the smelter clean-up.

Exide’s choice to risk an agreement that could give it $45 million in much-needed cash over the demolition of one remaining structure is curious. And it’s one that poses a challenge to the entire future the City of Frisco has laid out for the smelter site. If the City doesn’t buy the 179 acres of Exide property surrounding the smelter, it’s fate will be tied to the company’s and it might either become part of a future Superfund site or languish in a kind of real estate purgatory for a very long time.

That would more than double the size of the economic black hole the core plant site already poses for central Frisco. Frisco City Hall has come out in favor of locating a permanent toxic dump for Exide waste on that core property, but residents who are members of the local group Frisco Unleaded says there’s no reason to believe an Exide landfill would be run any better than an Exide smelter.

There's already been documentation of extensive lead contamination up and down Stewart Creek from the Exide property, through Grand Park and all the way to Lake Lewisville. Although the City of Dallas Water Utilities Department says that's not a threat to the city's drinking water because of its treatment facilities, the presence of a large landfill and/or Superfund site poses a danger of catastrophic releases that an operating smelter doesn't. And of course, recreational users of the Lake are being routinely exposed.

On February 26th, the Dallas Morning News identified competing plans for the clean-up of Stewart Creek as another source of tension between Frisco and Exide.

The only good news from this great unraveling is that it provides a chance to restart the public debate about what to do with the Exide site – a debate that was short-circuited by the council's settlement agreement that made everything seem like a done deal, even though its obvious now there were a lot of unanswered questions. There continues to be a need for a bottom-up, community wide discussion of what Frisco residents want to see happen with the site. Events in May might make that a more pressing priority.

End of an Era: TXI Cement Sold To Martin-Marietta

In a $2 billion deal, Raleigh, North Carolina-based aggregate and crushed stone manufacturer Martin Marietta Materials (a separate spin-off on the more well-know aerospace conglomerate) bought Dallas' own TXI Cement, which opened its first cement kiln in Midlothian in 1960.

In a $2 billion deal, Raleigh, North Carolina-based aggregate and crushed stone manufacturer Martin Marietta Materials (a separate spin-off on the more well-know aerospace conglomerate) bought Dallas' own TXI Cement, which opened its first cement kiln in Midlothian in 1960.

This year, that kiln, along with the three other obsolete wet kilns at TXI's Midltohian plant that burned hazardous waste for two decades, is due to be demolished, following the company's corporate demise at the hands of the grandson of its founder. And then, the last remnants of the old TXI will be gone for good.

What does the change in ownership mean for breathers in North Texas?

Martin Marietta has owned and operated cement plants around the US in the past, but they'd divested themselves of these prior to 2014. As of now, the TXI cement plants in Texas and California are apparently the only ones the company owns. There's some speculation that Martin-Marietta bought TXI for its aggregate, stone, and concrete facilities in Texas and California, and will soon seek a buyer for the cement plants it inherited, but doesn't really want.

If that's true, the new owners will act as placeholders of the status quo, not investing in big new capital projects, but also trying not to lose any of the value of the assets they now have by running them into the ground. Martin probably won't look favorably upon attempts to bring smog-reducing modern Selective Catalytic Reduction (SCR) technology to TXI via the next clean air plant for DFW, now due in June of 2015. Not only would the plant be among the first to adopt the technology in the US, (even though SCR has been successfully used in European cement kilns for over a decade now), but it would mean new capital investment and a new learning curve.

Swiss-based Holcim Cement, with a huge plant already in Midlothian and a large manufacturing footprint in the US, was rumored to be one of TXI's suitors before the sale was announced. It could be that Holcim, or another well-established player in the cement industry winds up with the actual kilns in the next year. That could complicate the plant's participation in the new clean air in other ways even if new owners are not as intimidated by the demand for new technology

Politically, it'll be interesting to see which Austin lawyers and lobbyists get the business of the new company. Martin-Marietta owns over 40 facilities in Texas already and is represented by it's own crew. Will TXI's law firm and lobbyists survive the buy-out? There are industry lobbyists that will keep the ball rolling no matter what – the Chemical Council, the Aggregate Association, etc. But in Austin, it's all about relationships, and it's hard to say yet how this Martin's buying of TXI changes any of them.

Maybe the place TXI's absence will be felt the most in in the corridors of power in DFW. TXI was proudly headquartered in Dallas. Ralph Rogers, TXI's founder and patriarch was a driving force in local philanthropy, giving millions to public broadcasting (KERA is housed is housed in the "Ralph Rogers Communications Center") and other non-profits. Besides feeing like he was entitled to use PBS's iconic Big Bird to sell the benefits of burning hazardous waste in 50-year-old cement kilns, the non-profit giving Rogers was responsible for made him a known figure on the Dallas Charitable circuit. In turn, this made it hard for the Powers That Be to criticize Roger's company when it became a waste incinerator.

Locally, the establishment played golf with the Rogers' or attended black tie dinners with them, or helped them lift the oversized scissors at ribbon-cutting ceremonies. But that was old Dallas. Hardly of those relationships survived past Ralph Rogers' death in 1997. His son, Robert, failed to maintain that same high-profile locally, and his grandson Jamie seems totally disinterested in the family business or its legacy of charitable giving.

Now, the move of company headquarters from Dallas to Raleigh will complete the disappearance of the once-mighty TXI on the local scene. They'll still be company representatives at functions, but it won't be the guy who can write the big checks, or who the Mayor had a splendid time with last Saturday at the Club.

The company's local political influence has forever been diminished, and that's a good thing for citizens who are fighting the company to get modern controls like SCR. Now, it's just one more corporate entity with a presence in North Texas. A presence that makes it the single largest air polluter in the region. That's the way Dallas and other downwind cities should have viewed the company all along.

Report: Homeowners Close to Frisco Lead Smelter Site Face 15% Drop in Property Values

Homeowners within a half mile of the former Exide lead smelter site and other lead-contaminated properties in Frisco are seeing a 15% drop in their property value from the stigma associated with the toxins, according to a new economic analysis done by an independent North Texas economist hired by local environmental groups.

Homeowners within a half mile of the former Exide lead smelter site and other lead-contaminated properties in Frisco are seeing a 15% drop in their property value from the stigma associated with the toxins, according to a new economic analysis done by an independent North Texas economist hired by local environmental groups.

“There are double-digit negative impacts on the assessed values of all 90 homes,” concluded Dr. Bill Luker, Director of Denton-based Terranovum Solutions, who was asked by Downwinders at Risk and Frisco Unleaded to examine the economic impact of the Exide environmental controversy on surrounding home values.

“There’s an average negative discount of $24,613,” stated Dr. Luker. “In other words, if it were not in close proximity to two sources of contamination, i.e., the Exide site and Stewart Creek, the average home would be assessed at about $213k, $24k more than its current appraisal of $189.3k.”

Dr. Luker said that although the study was relatively small in focus, he was confident of the results and said it pointed to the need by the City of Frisco to do its own more comprehensive economic analysis before it decides what environmental clean-up options to follow.

“The costs we’ve reported, while substantial for many homeowners, will be unquestionably dwarfed by the magnitude of those from the discounting of residential and commercial property values, and the negative effect on local personal income, employment, average and median household income, and ultimately, lost tax revenue for local government….”

Downwinders Director Jim Schermbeck called this economic impact a hidden “toxic landfill tax” that was already being assessed on the community now, in contrast to what some Frisco City Council representatives have said would be a necessary property tax increase to pay for a complete clean-up of the Exide property.

“City Hall may not want to talk about it, but there’s a heavy tax already being paid by Frisco property owners for being located in proximity to Exide. That tax will only increase and spread if a temporary clean-up of Exide is turned into a permanent landfill site for its toxic wastes.”

Monday at 5 pm was the deadline for government entities to put in their claims against Exide in the east coast bankruptcy court hearing the company’s case. Frisco City Hall has insisted that leaving a 40-acre toxic waste landfill behind on the Exide property will allow for normal economic development and a 4cheaper clean-up bill. The City has only asked the court for approximately $20 million for that option, versus the $135 million for a full clean-up.

But the city has yet to release an itemized accounting of their consultant’s cheaper estimate and this new report casts doubt that normal economic development can ever take place in the presence of so much toxic contamination.

According to Luker, “Re-development of the Exide site and surrounding property cannot occur if environmental remediation is viewed by the market as neither thorough nor complete. The net result of years or even decades of contamination will not only continue to depress values for both residential and commercial property, but will also hold down the growth of local private employment and levels of personal and household income. All of these factors will contribute to the indefinite perpetuation of economic underdevelopment in the center of Frisco.”

Schermbeck agreed. “This report is just the tip of the iceberg of likely economic problems caused by the City’s choice to allow a hazardous landfill to dump wastes improperly stored in Frisco to begin with . The total costs of keeping toxic waste in the middle of town could easily run into the billions in terms of lost taxes and lost economic opportunities. It’s in Frisco’s best interest to tally those costs up before they decide that it’s cheaper in the short run just to bury it in place downtown.”

He pointed out that it was Frisco Unleaded members who had already approached state legislators about redirecting state battery fees from general fund accounts to the Exide clean-up, something that Frisco City Hall had not yet committed to, despite tapping those funds during the last legislative session. “With state help you could totally remove the source of this economic stigma. You wouldn’t have to settle for a hazardous wast landfill in the middle of town. But the City won’t commit to this strategy.”

Schermbeck and Frisco Unleaded members have been criticizing the Frisco City Council for accepting the landfill option too quickly in light of so many unknowns of cost and contamination threat. They’ve asked for the city to release it’s own detailed consultant’s report on the different clean-up options, but so far City Hall has refused.

“There is a rush to judgment taking place within Frisco City Hall about the Exide site that’s totally at odds with the facts on the ground,” said Schermbeck. “This new study should be a big red flag to the City Council about its current course. The long term costs to the city ‘s economic growth may be larger than the short-term savings it thinks it will accrue by taking what looks like a cheaper option.”

You can download Dr. Luker's summary here.

Methodology: Dr. Luker’s economic analysis is a summary of impacts on property values of a sample of 90 homes in close proximity (between 3000 and 3600 feet) to the former Exide Corporation’s lead smelting operations in what is now downtown Frisco, TX. It uses reliable estimates drawn from the very broad and deep empirical literature on the statistically and commercially significant negative economic impacts of closely similar brownfield sites on residential property values in their immediate locale. For the year 2011, findings from that literature were used to calculate the negative impact on the assessed property values of 90 homes, a 3 percent non-random, spatially bounded sample from a population of 2782 homes identified within .5 to 1.5 miles of Exide-Frisco.

Know Your History

We've written about the founding of the modern environemental health movement at Love Canal, and the rise of housewife-to-hellraiser Lios Gibbs. As part of its "Retro Report" series of mini-films on past headline-making stories, the New York Times takes a look back and finds a continuing "Legacy of Doubt."

We've written about the founding of the modern environemental health movement at Love Canal, and the rise of housewife-to-hellraiser Lios Gibbs. As part of its "Retro Report" series of mini-films on past headline-making stories, the New York Times takes a look back and finds a continuing "Legacy of Doubt."

Study Reveals Cancer Hot Spots Downwind of Canadian Oil and Gas Processing Centers

On the heels of the World Health Organization declaring air pollution a carcinogen, a study published this week from the University of California-Irvine and University of Michigan found higher levels of specific carcinogens in communities downwind of Canadian "oil, gas and tar sands processing zones", and higher rates of Luekemia and non-Hodgkin’s lymphoma among men living in those downwind communities.

On the heels of the World Health Organization declaring air pollution a carcinogen, a study published this week from the University of California-Irvine and University of Michigan found higher levels of specific carcinogens in communities downwind of Canadian "oil, gas and tar sands processing zones", and higher rates of Luekemia and non-Hodgkin’s lymphoma among men living in those downwind communities.

Despite their rural location, the recorded levels of the carcinogens, including 1,3-butadiene and benzene, were higher than in some of the world's most polluted cities. Examining area health records that went back a decade showed the number of men with leukemia and non-Hodgkin’s lymphoma was greater in the communities closest to the pollution plumes.

The authors strongly recommended that the industrial emissions be decreased to protect both workers and nearby residents.

“Our study was designed to test what kinds of concentrations could be encountered on the ground during a random visit downwind of various facilities. We’re seeing elevated levels of carcinogens and other gases in the same area where we’re seeing excess cancers known to be caused by these chemicals,” said UC Irvine chemist Isobel Simpson, lead author of the paper in Atmospheric Environment. “Our main point is that it would be good to proactively lower these emissions of known carcinogens. You can study it and study it, but at some point you just have to say, ‘Let’s reduce it.’

Co-author Stuart Batterman, a University of Michigan professor of environmental health sciences, agreed: “These levels, found over a broad area, are clearly associated with industrial emissions. They also are evidence of major regulatory gaps in monitoring and controlling such emissions and in public health surveillance.”

Dr. Batterman is familiar to Downwinders old timers as being the first scientist to take on the state's laughable "Health Risk Assessment" of TXI's burning of hazardous waste at it Midlothian cement plant. In what became known simply as the "Batterman Report," his mid-1990's critique of the official document was devastating in its scope and depth. It became a template on how to deconstruct any TCEQ attempt to gloss over the dangers of living downwind of a large polluter.

In this new study, Dr. Batterman and his colleagues monitored emissions in the rural Fort Saskatchewan area downwind of major refineries, chemical manufacturers and tar sands processors owned by BP, Dow, Shell and other companies in the so-called “Industrial Heartland” of Alberta. Taking random one-minute samples in 2008, 2010 and 2012, the results were very similar over time – amounts of some of the most dangerous Volatile Organic Compounds were 6,000 times higher than normal. Higher than in Mexico City during the 1990s or in the still polluted Houston-Galveston area.

Simpson said the findings were important for other residential areas downwind of refineries and chemical manufacturers, including parts of Los Angeles.

“For any community downwind of heavy industrial activity, I would say it’s certainly prudent to conduct surveys of both air quality – especially carcinogens – and human health."

“March of the Incinerators” is Killing Recycling in Britain

For the first time in 30 years recycling rates in the UK are going down and a influx of incineration capacity is being blamed.

For the first time in 30 years recycling rates in the UK are going down and a influx of incineration capacity is being blamed.

New European Union directives favoring waste burning over recycling are now spreading throughout Great Britain and having a big impact. Landfill disposal has gone down by almost 50% in just over a decade. Meanwhile there are now 39 incineration plants in the UK that have either been built are under construction or are at the planning stage – so many that there are now concerns about overcapacity. Moreover, every time an incinerator is chosen over other options, it institutionalizes the economics of incineration.

Experts said the use of incinerators had consequences for recycling as local authorities were forced to divert waste to feed the plants. "The choice to invest in thermal treatment can hold back recycling efforts," Adam Baddeley, principal consultant at Eunomia, said. "At one level, the money invested in such plant simply isn't available to put into building recycling plants or collection infrastructure. And once you've built an incinerator or gasifier, there's a strong incentive to keep it fed with waste, even if that means keeping on collecting as 'black bag' rubbish, material that would be economically practicable to collect separately for recycling."

Because Texas is still home to relatively cheap and abundant land, it hasn't seen the wave of incinerators that swallowed up the budgets of East Coast and Midwestern towns throughout the 1980's and 90's. But that may be about to change with increased urbanization, the desire of cities to profit from their garbage somehow, and new regs that are written to encourage incineration of "biofuels" that can include waste. Some local observers think it's only a mater of time before a large garbage incinerator is proposed for the Dallas area.

But why wait when you've got three large cement plants down the road?

Hazardous waste was burned in two out of the three Midlothian cement plants for decades and now all three are burning different kinds of solid wastes, including tires, car parts, and "non-recyclable" plastics. They're the front line in the March of Incineration in North Texas.

Behind Last Week’s Ash Grove Headlines: “The Rest of the (20 year) Story”

There was a great deal of official news fluttering last Thursday when the EPA and Department of Justice announced a national settlement with Kansas-City based Ash Grove Cement that confirmed the company's Midlothian plant, site of The Last Wet Kilns in Texas™, would shut down and covert to one large dry process kiln by September of next year. Both dailies reported like it was 1999, with front page headlines and lots of column inches (ask your parents).

There was a great deal of official news fluttering last Thursday when the EPA and Department of Justice announced a national settlement with Kansas-City based Ash Grove Cement that confirmed the company's Midlothian plant, site of The Last Wet Kilns in Texas™, would shut down and covert to one large dry process kiln by September of next year. Both dailies reported like it was 1999, with front page headlines and lots of column inches (ask your parents).

But the newsworthy part of last week's developments was not that Ash Grove was converting its wet kilns to a dry kiln. In February of last year, Downwinders at Risk reported that the company was seeking a permit from the Texas Commission on Environmental Quality to do just that. The Star-Telegram, bless their hearts, even wrote a story about it. Ash Grove's planned conversion was so widely-known that it was the subject of Midlothian Rotary Club meeting speeches this last Spring. So, you know, not news.

It wasn't news because those new national EPA air pollution rules for cement plants that we all drove out to DFW Airport in 2009 to testify in favor of and then to Arlington last year to defend, were expected to put the final nail in the coffin of Ash Grove's wet kilns by the time they took effect in September 2013. TCEQ granted the company a lame one-year extension to the 2013 deadline, but by September 2014, it was pretty clear that Ash Grove's Midlothian wet kilns would have to be converted or replaced to meet those new EPA standards coming down the pike. That's why last year's permit application for the conversion wasn't a surprise, but a confirmation.

And then the Obama Administration decided to stop the standards from coming down the pike. Just as those rules and that 2013 deadline was about to be signed into law, the President changed his mind and put them on hold. His EPA weakened the air pollution standards as proposed and delayed the deadline until 2015 or later – against overwhelming public opposition. All of a sudden, that 2014 deadline for an Ash Grove conversion looked to be in trouble. Would The Last Wet kilns in Texas™ just keep chugging along?

But what do you know? As part of that national settlement announced last Thursday, Ash Grove committed to the government to make the conversion and run the new dry kiln starting in….September 2014, or the original date of dry kiln conversion before the Obama u-turn on the new rules. What a coincidence!

So what was REALLY newsworthy about last week's announcement was that the national EPA managed not to screw-up a very good thing that its now-abandoned tougher rules were already putting in motion on the ground in Midlothian. Lucky us, huh?

The luck had some help from Downwinders. We knew the EPA was looking at Ash Grove for the kind of national enforcement settlement it had cut with LaFarge and other cement companies as part of its multi-year spotlight on the industry. We knew that the former Regional Counsel for the EPA office in Dallas, Larry Starfield, who spent decades dealing with all three Midlothian cement plants, was now in DC as EPA Deputy Enforcement Director, and probably in line to sign-off on any agreement. And we knew the original 2014 deadline for Ash Grove's conversion was in trouble with the Administration's reversal on the new air pollution standards.

We made inquiries, We made pitches. If Ash Grove were the subject of such a national enforcement effort, would it be possible for EPA to please consider requiring Ash Grove's Midlothian plant to firmly commit to its 2014 conversion deadline as part of any settlement? Turns out, it was possible.

How likely would it have been without our intervention? Best not to ask. But if you think, as we do, that our showing-up and making the case made a difference in securing progress that was in danger of being further delayed, here's the tip jar.

So yea for our side, although the victory seems a little less satisfying than what it should be when you know it's simply maintaining the status quo. Still, it's better than another couple of years of pollution from the area's dirtiest smokestacks.

$2.5 million in fines plays well in headlines until you realize how small it is compared to company's annual profits (almost $900 million n 2010). Beside the fines, nine Ash Grove plants will have to better control their smog-causing Nitrogen Oxide, Particulate Matter and Sulfur Dioxide pollution better, including the installation of Selective Non-Catalytic Reduction, or SNCR technology. The Midlothian plant was already scheduled to have this included in its conversion in order to meet those now-abandoned new air pollution standards. There's also a strong possibility that Ash Grove's other wet kilns will follow Midlothian's lead and also be converted to dry kiln technology.

Unfortunately, EPA didn't require any new testing of Selective Catalytic Reduction Technology, as it had in previously announced cement company settlements. SCR is twice as effective at cutting cement plant pollution as SNCR and has been used on kilns in Europe for over a decade. It's state of the art. But it's still not required in the US, although the results from two EPA-mandated pilot tests on kilns in the Midwest are due this year. One good thing about Ash Grove's conversion is that the plants can no longer use their continued operation of obsolete wet kilns as an excuse not to install modern equipment like SCR as it has in the past – although we know they'll find a new excuse now.

Here's the consent decree if you want to read all the details of the settlement. And here's the original complaint, which chronicles the alleged misdeeds of the company, plant by plant, including the sins of the Midlothian facility. A lot of the legal case depends on parts of the Clean Air Act that says any "major modification" to a plant must not increase pollution. Ash Grove ignored this law. Repeatedly. Over the last 20 years. According to the complaint, the violations in Midlothian originally occurred in 1995. That's right, it's taken almost 20 years for EPA to enforce a basic Clean Air Act violation.

"Kilns 1, 2, and 3 at Ash Grove's facility in Midlothian, Texas: 1) in or around 1995, Ash Grove performed a project to re-route ductwork that transports hot air from Midlothian Kiln 1 to the coal mill and performed a project to enable Kiln 1 to burn waste whole tires as a fuel source; 2) in or around 1995, Ash Grove performed a project to re-route ductwork that transports hot air from Midlothian Kiln 2 to the coal mill and performed a project to enable Kiln 2 to burn waste whole tires as a fuel source; and 3) in or around 1995, Ash Grove performed a project to re-route ductwork that transports hot air from Midlothian Kiln 3 to the coal mill and performed a project to enable Kiln 3 to burn waste whole tires as a fuel source."

Downwinders has always argued that tire-burning increases emissions, not decreases them as the industry maintains. We were saying this in 1995 as these illegal changes were taking place and Ash Grove officials were saying what a great air pollution control strategy it was to burn whole tires.

The implications of these kind of very common violations hang heavy over the current industry transition to new and more exotic industrial wastes being burned in kilns, some of which make tires look like Grade-A fuel oil. Plastics, shingles, car parts. All of the Midlothian cement plant are now burning things that they shouldn't be with no more assurance they aren't breaking the law than there was in 1995 when they were changing fuels then. But don't worry, EPA's on the case and you can expect any such violations to be prosecuted in….2033.

Latest Stop in Slo-Mo Exide Train Wreck: Thursday 5-7pm

Coming down the hill from the west is a freight train full of woe for Exide. It's carrying at least five shareholder lawsuits aimed at the company for not disclosing its environmental liabilities, including those stemming from the operation of its Vernon, California smelter. That would be the same smelter California state officials shut down due to leaking lead waste and an unacceptable cancer risk to over 100,000 local residents. On board is a "restructuring specialist" who is supposed to see the company through its second bankruptcy in a decade. As of last week, Exide stock was selling for a cool 75 cents a share. The whole company is about to shoot off the rails.

Coming down the hill from the west is a freight train full of woe for Exide. It's carrying at least five shareholder lawsuits aimed at the company for not disclosing its environmental liabilities, including those stemming from the operation of its Vernon, California smelter. That would be the same smelter California state officials shut down due to leaking lead waste and an unacceptable cancer risk to over 100,000 local residents. On board is a "restructuring specialist" who is supposed to see the company through its second bankruptcy in a decade. As of last week, Exide stock was selling for a cool 75 cents a share. The whole company is about to shoot off the rails.

Meeting it head-on coming from the east is the Exide's smelter site in Frisco, over 100 acres and fifty years of sloppy handling and disposal of hazardous lead, arsenic, cadmium, dioxin and other poisons. There are "pre-RCRA" sites aplenty – meaning they were there before any regulations could catch up with them, as well as more recent disasters like the illegal burying of hazardous waste in a non-hazardous landfill. Just last week the City of Frisco released a preliminary environmental assessment of the LEAST-contaminated parts of the smelter that revealed new potential contamination as well as the fact that the entirety of Stewart Creek had been re-routed around the smelter in 1964 – leaving the original channel underneath the MOST contaminated part of the smelter. Moreover, even though the smelter closed in November of last year, it's been routinely causing high levels of lead air pollution from the demolition and closure operations going on.

Caught in the middle are Frisco residents who just want to live without a lot of lead in their air for awhile, and don't want to see a new Superfund Site in their town. The state's Texas Commission in Environmental Quality is in its usual "Yes Man" role to industry and seemingly finds no fault in any of Exide's plans to leave pits and landfills full of smelter waste in Frisco permanently. Having made its sweetheart deal to close the smelter, the City of Frisco has taken a back seat to the company and TCEQ when it's come time to figure out how best to clean-up the site.

Thursday night Exide is sponsoring another one of its "community meetings" in which the community is invited to come hear company representatives put nice spin on everything as well as duck questions about its financial responsibilities and long-term plans. It's no substitute for a real public meeting but its the only game in town for Frisco residents who don't want to see a toxic waste dump site remain downtown.