Posts Tagged ‘SCR’

We Did It: After 15-Years of Persistent Organizing, Citizens Finally See Modern Controls on a Midlothian Cement Plant. And Now We Want It on All of Them

Holcim is the first cement plant in the nation to voluntarily install an industrial catalytic converter called SCR on its smokestack, significantly cutting smog-forming air pollution in DFW.

Holcim is the first cement plant in the nation to voluntarily install an industrial catalytic converter called SCR on its smokestack, significantly cutting smog-forming air pollution in DFW.

But despite operating only 26 miles from EPA headquarters, the Agency and State of Texas still claim the technology isn't "feasible"

Downwinders is proud to announce Midlothian's Holcim cement plant is the first in the nation to voluntarily install pollution control equipment significantly cutting smog-forming air pollution, along with other dangerous emissions.

"Not many people may notice, but Friday is a big day for air breathers in DFW, as well as for everyone in the country who lives downwind of a cement plant," said Tamera Bounds, Chair of Downwinders at Risk, the clean air group that's been relentless in its pursuit of the technology for North Texas since 2001.

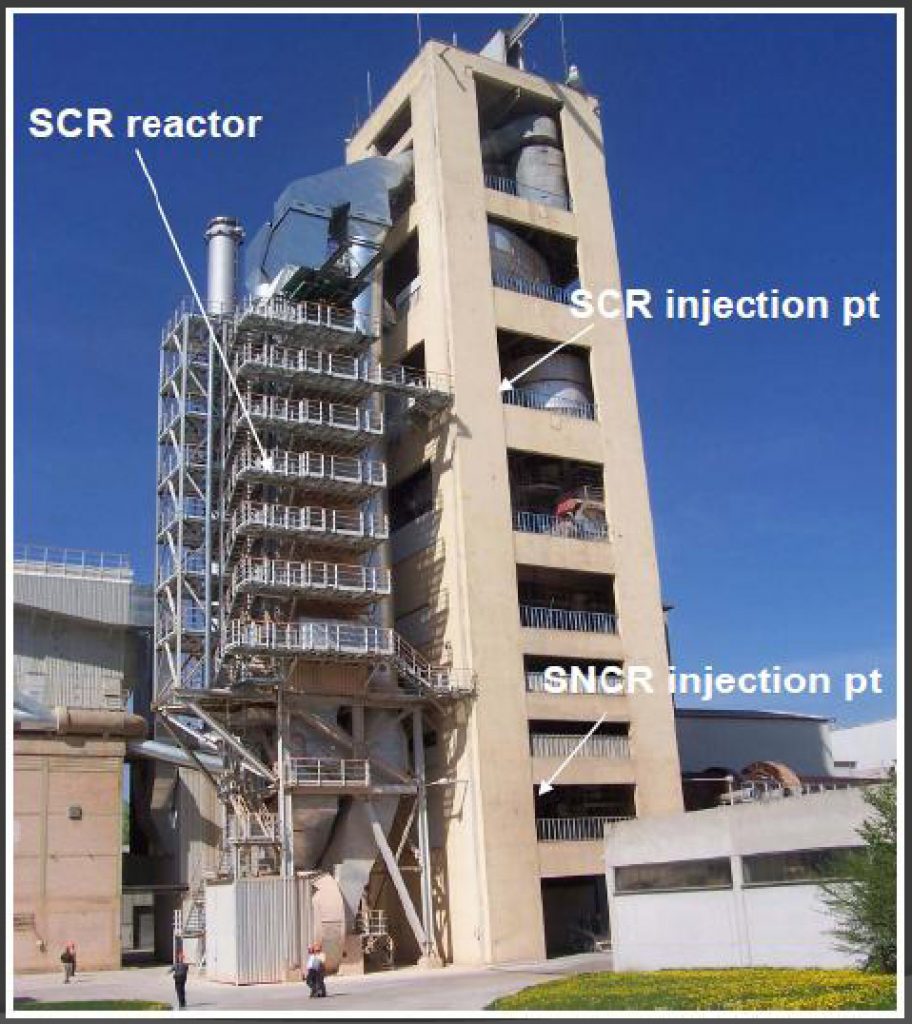

Friday marks the official deadline for Holcim's Midlothian cement plant to have its Selective Catalytic Reduction, or SCR system, up and running on one of its two giant kilns in order to be compliant with EPA emissions limits.

Although almost a dozen cement plants in Europe have installed the technology over the last twenty years and it's widespread in the American coal industry, Holcim is so far the only cement plant in the U.S. to install SCR on one of its kilns without a government mandate.

A pilot test using SCR at Midwest cement plant was required by a Department of Justice enforcement action in 2010. Results show smog-forming pollution was cut by at least 80% – roughly twice as much as pollution controls now in use in the US, including Midlothian. In Europe, SCR has a track record of removing 80-90% or more of the smog-forming pollution that has kept DFW in violation of the Clean Air Act since 1991. It also cuts the emissions of air toxics, particulate matter, and dioxins by double-digits.

With three cement plants and four kilns, Midlothian hosts the largest concentration of cement manufacturing in the US, and the largest "stationary" sources of air pollution in DFW. Since the late 1980's, the city has become a national battleground over cement plant pollution. First, over the use of hazardous waste as "fuel" for the local kilns, then over the closing of dirtier, obsolete "wet" kilns contributing to smog and climate change, and now over how fast new kilns can be updated to reflect 21st technology.

Bounds and others say the installation of SCR on all four kilns in Midlothian would mean a huge benefit to public health for residents in Tarrant County, where the predominant winds push the plumes from the kilns. A 2009 Cook Children's Hospital study showed childhood asthma levels highest directly downwind of the cement kilns.

The demand for the technology is a central part of the group's push to replace the current State-sponsored anti-smog plan with a more effective, and protective, one from EPA. So far, Dallas County, the City of Dallas, two Congressional Representatives and a State Legislator agree with them. But incredibly, the Agency maintains the SCR technology Holcim has freely invested in to reduce pollution and is already operating less than 30 miles from its regional headquarters is not "technically feasible."

Downwinders and other groups in the DFW Clean Air Network regional alliance are challenging EPA's refusal to recognize a game-changing pollution control technology that could help DFW finally put its smog problems behind it a well as offering similar help to other parts of the country downwind of cement plants.

"It's rare these days to find the EPA embracing Texas' approach to ignoring advances in environmental science, but that's exactly what happening," said Bounds. "Both State and EPA officials are acting like 3rd Graders – closing their eyes and humming loudly, pretending this time-tested technology isn't operating right in front of them. But it does, and it's here to stay."

Bounds wants the EPA to take note of the cuts in pollution triggered by Holcim's operation of its SCR system and then hold ALL the Midlothian plants to the same modern standard. "You have a piece of equipment that is setting a higher bar for pollution control. Every cement kiln in DFW should have to meet that higher bar now. No other anti-pollution strategy makes sense."

It's been a long and circuitous route to getting SCR installed in a Midlothian cement kiln. Along the way, the region's clean air activists moved the entire nation closer to widespread use of this control technology.

North Texans first heard about the use of SCR in the cement industry through a citizens group fighting a proposed new cement plant in New York state in 2001.They'd commissioned a study from a NYC engineering firm identifying European cement plants that had already successfully installed the technology.

Downwinders tried and failed to include SCR in the anti-smog plan in 2003. It then used a 2005 settlement agreement with the State over the failure of that plan to get the then Rick Perry-controlled Texas Commission on Environmental Quality to perform an independent assessment of the technology. That landmark study produced results that are still reverberating today. In it, five independent experts chosen by Downwinders, the cement industry, and the State declared SCR to be ready for prime time.

"SCR is a commercially available technology. It offers the possibility of significant NOx reduction at the plants in Ellis County. As an 'add on' technology, which can achieve 90% or greater NOx reduction, with demonstrated performance at hundreds of coal fired power plants, SCR is a viable technology that is available for both dry and wet kilns."

That conclusion, from cement industry experts, in a TCEQ study, is now a decade old.

At the same time they were working to bring SCR to Midlothian, Downwinders also led the fight for new EPA emission limits on cement kilns that burn hazardous waste. A 2009 national hearing at DFW Airport attracted over 200 people. Those emission limits clamped down on air toxics. Holcim couldn't meet them without adding controls. They choose an SCR unit on one kiln and a thermal oxidizer (re: flame) on the other to try and stay in compliance. Even though Holcim installed SCR to address air toxics, or Volatile Organic Compounds and not smog pollution, the effect on emissions will be the same.

Meanwhile, the 2006 TCEQ study and subsequent push by Downwinders for SCR in Midlothian helped persuade the EPA to require the pilot test in 2010. That test, as well as Holcim's experience in Europe, set the stage for SCR's official debut on the Texas prairie on Friday.

"It's been a long fight, but change is hard," said Bounds, "and it doesn't happen in a straight line."

Help Us Celebrate This Victory That Was 15 Years in the Making

Please consider contributing $25 or more on "GIVING DAY" NEXT THURSDAY to keep us on the front lines of change another 15 years.

Giving Day is an all day online giving event sponsored by the Communities Foundation of Texas.

Downwinders will have our own online Giving Day page where you can click and give from 6 am through 12 Midnight next Thursday.

Every contribution of $25 or more is matched or extended by the Foundation.

This year, we need your support to keep our full-time staff in the field, as well as fund our 2nd annual Root and Branch Revue for activists, and assemble our North Texas Clean Air Forceof air-monitoring drones.

Oh yeah, we're also opening a school for organizers in January.

We're based in DFW. All our board members are from DFW. Our priority is DFW air. Your contribution stays in North Texas to fund the fight for clean air in North Texas.

We know you're being assaulted by Giving Day appeals from all the local non-profits, and there are lots and lots of good causes. We only request that you ask yourself how many other local groups can repeatedly pull off meaningful victories with so few resources?

We were able to bring SCR to Midlothian with your help. We need your help again next Thursday. We think we've earned it.

Thanks.

US Cement Plant Using SCR Pollution Control Device Achieves 80% Reduction. Texas Says It’s Still Not Feasible.

EPA has released the results of the first test of a full-scale Selective Catalytic Reduction (SCR) unit on a US cement plant and the numbers look good.

EPA has released the results of the first test of a full-scale Selective Catalytic Reduction (SCR) unit on a US cement plant and the numbers look good.

As many of you know, SCR is just an industrial-sized version of the catalytic converter in your car. It can capture up to 90% or more of the smog-forming pollution from a cement plant. In use on cement kilns since 2001, there are at least a half a dozen cement plants in Europe that use SCR successfully, but the technology has been slow to arrive in the US because of regulatory laziness and industry resistance.

But after 15 years, that's finally changing.

in 2013, LaFarge Cement entered into a consent decree with the EPA and the US Justice Department as part of a settlement over a string of environmental violations, including excessive smog-forming Nitrogen Oxide (NOX) emissions. As part of that settlement, Lafarge was to retrofit its Joppa, Illinois "dry process" cement kiln with an SCR unit, record its effectiveness during stack testing, and report on the results of those tests by 2015.

This last week, those results were finally made available by EPA and they show SCR was able to reduce NOx by 80%.

That's approximately twice as effective as SNCR technology, (Selective NON-Catalytic Reduction), the current pollution control device for NOx most often used in U.S. cement plants.

Moreover, according to LaFarge, "the SCR control technology performed well and no operational problem was encountered."

In fact, the control technology worked so well, LaFarge is now getting a permit from the Illinois state environmental agency to operate SCR past the EPA-mandated settlement period.

But while LaFarge is getting its SCR permit, Holcim's Midlothian cement plant has already applied and been granted one by the Texas Commission on Environmental Quality for construction and operation of its own SCR unit. It should be up and running by this time next year.

So that makes two U.S. cement plants with permits to run full-scale SCR units. One that was forced into the choice by EPA and now wants to keep using it, and another voluntarily adding it.

But according to the TCEQ, even though it gave a permit to Holcim to install SCR, and even though Holcim's SCR unit will be operational in a year, and even though the LaFarge test was a success, and even though SCR has been used for 15 years by European cement companies – SCR is "not economically or technically feasible." That's exactly what the Commission said in response to comments from both citizens and the EPA in its new clean air plan for DFW a couple of months ago.

That's right. One the one hand the Commission has granted a permit to Holcim to build an SCR unit in its own backyard, and on the other it's still calling the technology infeasible. It's the stuff of Monty Python sketches.

And that's not all. There is no mention of the Holcim Cement SCR permit in the TCEQ's own official arguments against SCR in its DFW clean air plan. Not one. Since Holcim's building of an SCR unit would tend to empirically disprove TCEQ's contention that the technology wasn't practical, the state just pretends it's not happening. As with climate change and smog, any facts that conflict with the pre-determined ideologically-correct premise must be ignored.

Presumably, Holcim is building the SCR unit because it's made the business judgment that the technology is not only both economically and technologically feasible, but beneficial to the company's bottom line. Presumably LaFarge is pursuing a permit for its SCR unit because it has made the same practical decision. Yet, in a strange role reversal, a Texas state government agency is now telling business it's making the wrong choices. It's overruling the industry's decision to reduce pollution through SCR use by saying "not so fast."

This is how bad its gotten: the Texas approach to clean air is now so backwards that the cement industry is more aggressive about reducing pollution than Austin.

So how many U.S. cement plants have to be operating with SCR before the State of Texas concludes it's a feasible technology? Two? Four? A Dozen?

Fortunately, the TCEQ isn't the last word on this. The Clean Air Act says any and all reasonably available technology must be used on major pollution sources like the Midlothian cement plants when a clean air plan is being drafted. TCEQ hasn't done that. We think they're breaking the law. There are signs that EPA thinks so as well.

EPA is ultimately in charge of enforcing the Clean Air Act, and if it doesn't do it correctly, then the courts step in.

The best hope for safe and legal air in DFW is for EPA to rigorously enforce the law. The State of Texas will not do so. If you agree then please take a minute to:

1) sign this petition to EPA

2) Send this e-mail to EPA

Thanks.

State Public Meeting Tonight on New Permit for Holcim’s Midlothian Cement Plant

There's a public meeting hosted by TCEQ at 7pm tonight concerning the new permit for Holcim's Midlothian cement plant. It's taking place at the Midlothian Conference Center, at 1 community Center Road, right off Hwy 287. Here's a map if you need one.

There's a public meeting hosted by TCEQ at 7pm tonight concerning the new permit for Holcim's Midlothian cement plant. It's taking place at the Midlothian Conference Center, at 1 community Center Road, right off Hwy 287. Here's a map if you need one.

This is your only chance to ask questions and raise concerns about Holcim's new permit, or any other aspect of Holcim operations in a public forum in 2014.

Remember that Holcim's pollution contributes to higher smog levels as far north as Denton and Wise Counties. Along with TXI and Ash Grove, its plumes have been associated with higher childhood asthmarates in southeast Tarrant County.

Holcim is also still the only Midlothain cement plant still blasting for rock. The others use machinery to mine limestone, Holcim uses ammonium nitrate, the same explosives that caused the West, Texas catastrophe.

The good news is that Holcim has decided to install Selective Catalytic Reduction (SCR) pollution control on one of their two large cement kilns. That's what the new permit mostly is about. Although well-known for reducing smog-forming Nitrogen Oxide (NOx) in the European cement industry, Holcim is using it to reduce Total Hydrocarbons – a category of pollutionthat includes toluene, benzene, and xylene.

You can read about how important a victory SCR is for all DFW breathers here. It's been a 15 year effort. Holcim's decision to install SCR should be celebrated.

But important questions remain about when the SCR unit will become operational and how reductions in airpollution like NOx will be tracked by the company.

SCR is only being installed on one of two Holcim kilns in Midlothian. The other kiln is getting a "Regenerative Thermal Oxidizer" – the equivalent of a flare on a gas well – to burn off its total Hydrocarbons.

Because they're combustion-based, RTOs increase NOx pollution. How much, and how Holcim can catch that increase before it goes up the stack is alsothe subject of the permit.

The public meeting on Monday is not a hearing. But it is the only public forum where citizens can thank Holcim for finally installing SCR, as well as express their concerns and ask questions about the permit.

We know it's a busy time of year, and it's the day before Election Day, but do your lungs a favor and attend a meeting about a permit that can affect them for good or bad.

After a 14-year Campaign, State-of-the-Art Pollution Control Finally Coming to Midlothian

(Midlothian) After a 14-year effort by local citizens, Holcim US Inc. is applying for a permit to the Texas Commission on Environmental Quality to install a Selective Catalytic Reduction (SCR) unit in their Midlothian facility. It's the first application for commercial use of SCR technology in any U.S. cement kiln.

(Midlothian) After a 14-year effort by local citizens, Holcim US Inc. is applying for a permit to the Texas Commission on Environmental Quality to install a Selective Catalytic Reduction (SCR) unit in their Midlothian facility. It's the first application for commercial use of SCR technology in any U.S. cement kiln.

DFW-based clean air group Downwinders at Risk has been advocating the use of SCR in the three Midlothian cement plants located just south of I-20 since 2000, when a German cement kiln first operated the technology successfully.

Together, the TXI, Ash Grove, and Holcim plants represent the largest concentration of cement manufacturing in the country and are a major contributor to DFW's historic smog problem.

"We need this pollution control technology in North Texas, and we're pleased to see Holcim's application," said Downwinders Director Jim Schermbeck. "But we wish residents could enjoy its results sooner than Holcim intends."

The SCR unit is planned for Holcim's idle Kiln #2 while a more common Regenerative Thermal Oxidizer will be built for its operating Kiln #1. Both technologies are being installed to meet new EPA emission standards for hydrocarbon pollution from cement plants. Those standards themselves were championed by Downwinders and other citizen groups in 2009, with over 200 people showing up at an EPA hearing the the DFW Airport Hotel to support them.

The deadline for compliance with the new standards is September 2016. However, restarting of Kiln #2, and the introduction of SCR in Midlothian, is dependent on local demand for Holcim's cement, which is still recovering from weak demand during the recession. That lack of demand could delay the technology's inauguration until after 2016.

Nevertheless, according to Schermbeck, Holcim's application for a permit to install SCR makes it's more likely that all of the Midlothian cement plants, and others in EPA "non-attainment areas" for smog pollution around the country, will be adopting it sooner rather than later.

"Holcim's application sets a precedent that's hard to ignore by regulators in Austin and Washington. For the first time a US cement plant has expressed enough confidence in SCR to make it a technically and economically-viable choice for pollution control. There's no going back."

SCR is widely considered to be the most advanced form of pollution control for cement manufacturing, capable of reducing smog-forming pollution by 90% or more, along with significant reductions in Particulate Matter, metals, and Dioxins.

Although about half a dozen European cement kilns are successfully operating the technology, U.S. plants have refused to endorse it. Two EPA-sponsored pilot tests of SCR are being conducted at Indiana and Illinois cement kilns as part of court-ordered settlements. Holcim's application for its Midlothian kiln is the first time and American cement plant is voluntarily approving SCR use.

Although it's not coming in time to impact the current DFW clean air plan, due to go to public hearing in January of next year, Holcim's application will put SCR on the agenda for the next such plan.

Just two weeks ago, EPA staff recommended a new ozone, or smog, standard of between 60 and 70 parts per billion over an eight hour period versus the current limit of 75 ppb. Adoption of a stricter standard is expected to occur by late next year, meaning a plan to meet that standard will be gearing up sometime in the next three to five years. By that time, Holcim's SCR unit should have a track record that can be cited as a reason for all the Midlothian cement plants to use it.

Schermbeck noted that just last month representatives of the TCEQ told a regional air quality meeting in Arlington that SCR was neither an economical nor technically feasible pollution control option for the Midlothian cement plants. He said Holcim's application belies that claim.

A public meeting on the Holcim permit application is being scheduled for early November.

Arrival of SCR on the scene marks the latest and the most dramatic milestone in the transformation of the local cement industry since Downwinders at Risk was founded 20 years ago to stop the burning of hazardous wastes in the Midlothian kilns.

After a 14-year battle, TXI halted its hazardous waste-burning operations in 2008. Downwinders then pursued a six-year "green cement" campaign to replace all seven obsolete and dirtier wet kilns with newer "dry kiln" technology. That campaign ended in 2012 with the announcement that Ash Grove would shutter its three wet kilns and build a new dry kiln in their place. That plant is due to go on line this year.

Adoption of SCR remained a goal of the group through four different DFW clean air plans going all the way back to 2000. Schermbeck said his group made incremental progress each time, winning small and large battles that directly lead to today's news.

"Holcim's application for SCR is the latest testament to the persistence and focus of a small group of committed citizens who have pulled and pushed the U.S. cement industry into the 21st Century one step at a time."

TCEQ: Link Between Fracking and Air Quality, No Cement Controls Just “Because”: Highlights From Tuesday’s Air Meeting

Dallas Resident Liz Alexander showed up at the Council of Governments meeting room on Tuesday to lend her support to the effort to get more out of an anemic state ant-smog plan than the state wants to give. She was a warm body whose presence would be its own statement of concern. She was being a good trooper by just showing up.

Dallas Resident Liz Alexander showed up at the Council of Governments meeting room on Tuesday to lend her support to the effort to get more out of an anemic state ant-smog plan than the state wants to give. She was a warm body whose presence would be its own statement of concern. She was being a good trooper by just showing up.

At first she sat far from the action amidst the rows of seats for bystanders and, despite encouragement, was resigned to just listening, because as she explained, "she didn't know enough to ask questions."

Then someone urged her to move up to the rectangle of tables where the presenters stand and deliver, where there are microphones to raise the volume of concerns and questions that might be posed by mind-numbing reassurances that everything is going hunky-dory. As more of these air quality meetings have occurred, citizens have been less and less shy about taking up these front row seats that look more official than the rest; look like they should be reserved for guys in suits. Increasingly they're occupied by people in street clothes.

And then, after much information had been paraded in front of Liz, she did something she did not think she was qualified to do only about 90 minutes earlier. She asked a question. It was about what assumptions had been included in the information about unspent air pollution clean-up dollars that are piling up in Austin. She got an answer from a local COG staff person in real time that satisfied her. In the space of one meeting she moved from spectator to participant.

And she wasn't the only one. More than any other meeting so far, this one involved more citizens asking more questions about more subjects – and it revealed just how thin the state's rationale is for doing nothing.

As predicted, it was a day for the Texas Commission on Environmental Quality to explain why its new DFW anti-smog plan was really going to work this time – unlike the five previous failures – and why it wasn't going to be considering any new controls on the Midlothian cement plants or on gas compressors – a refutation of the case Downwinders at Risk had made in its June 16th presentation.

But here's what really happened: For the first time in these proceedings the state admitted that oil and gas emissions have a big influence on regional air quality. And when a former County Judge asked an TCEQ's Air Quality Manager specifically why anti-smog controls already being used on cement kilns in Europe were not being considered for the Midlothian kilns, the staffer couldn't say, offering up only the longest, most pregnant pause by any state staffer in the history of these meetings.

After being heavily criticized for months for leaving at least four monitors above the 75 ppb federal smog standard even after its plan had ended in 2018, the state came back to this meeting saying they only had three sites above 75 ppb now, and by margins that didn't exceed the standard by more than 1 part per billion. Between June and August, there had been a remarkable drop in future estimated smog levels at the area's monitoring sties in the state's computer modeling – particularly at the historically most stubborn monitoring sites in Denton and Northwest Tarrant County.

What had caused this drop? A relatively modest decrease in Nitrogen Oxide pollution of around seven tons a day and a decrease in Volatile Organic Compounds of about 15 tons per day. That's not a lot of pollution to produce such a large decrease in monitor readings in the computer model.

A more important question is: where did the decreases in air pollution come from that could produce such dramatic results in the modeling? The answer: primarily from oil and gas industry sources. Based on TCEQ's own formula relying on the declining number of new wells being drilled in the Barnett Shale.

For the moment forget the methodological qualms you might have about that declining well assumption. Instead, appreciate the fact that the same state agency that couldn't bring itself to ever say the Barnett Shale was producing air pollution holding DFW back from meeting Clean Air Act smog standards now says that it's decreases in that very kind of pollution that are having such a substantial effect on the monitors in the western part of the Metromess that have been the most resistant to other control strategies. TCEQ has just proven a causal link its been denying for over seven years now.

It can't be just a one-way street. If declining oil and gas air pollution equals better air quality in the TCEQ's computer model, so increases in oil and gas pollution must lead to worse air quality.

There are all kinds of reasons to doubt that the drop in total oil and gas air pollution will happen at all or drop as fast or as sharply as the TCEQ predicts. Afterall, they're 0 for 5 in such matters. They may be underestimating the amount of total air pollution from all gas and oil sources and so the drop will not be as sharp. They may be underestimating the impact of lots of new lift compressors that will be showing up to squeeze the last bits of gas from older wells even as new wells are not drilled as often. But as of Tuesday the link has been made by TCEQ itself that such a drop results in big decreases in smog levels in Denton and Northwest Tarrant County. That's something that citizens can use to argue as proof of the impact of oil and gas facilities on local air quality.

Of course, it only took the span of about 30 minutes for the TCEQ to internally contradict itself about those results.

According to TCEQ computer modelers, natural gas Compressor Stations large enough to be considered "point sources" just like cement kilns or power plants will be responsible for over 17 tons of Nitrogen Oxides, and 26 tons of VOCs a day in 2018 – well over the amount of oil and gas pollution decreases that resulted in those lower monitoring numbers in Denton and NW Tarrant County. But according to the TCEQ staff responsible for suggesting new controls in the new smog plan, those numbers are not large enough to have an impact on improving DFW air quality or warranting a policy of electrification for those compressors that could reduce their air pollution to a fraction of those volumes.

So while 7 tons of NOx reduction from Oil and Gas sources is large enough to bring some of the most stubborn monitors down a whole part per billion, reducing air pollution from Oil and Gas sources by another 17 tons of NOx reduction would have no effect on DFW air quality at all and it's just not worth it to make them electrify compressors. Honest, that was the logic in play on Monday, and it didn't hold up very well under questions from people like Liz Alexander.

And that was all before you got to why the Midlothian cement kilns could not, no way, no how, possibly, under any circumstance, be required to install Selective Catalytic Reduction controls, just like their European counterparts have done over the last 15 years.

Turns out, it's just because.

Oh, the TCEQ staffer cited four criteria for any new control measure to meet before it could be considered. Let's see, there was "technological feasibility." Since there are at least seven full-scale SCR units up and running in Europe, that couldn't be a problem. It's accepted technology by some of the same companies operating kilns in the US – including LaFarge-Holcim.

There was "economic feasibility." And since there are all those SCR examples already in the European market and no company has gone bankrupt running them, that's also off the table. Plus the fact that the TCEQ's own 2005 study of SCR concluded it was "available technology" then that would only cost $1000 to $3,000 per ton of NOx removed – versus the up to $15,000 per ton of NOx removed ratio allowed in the state's own official diesel engine replacement program. Coming in at one-fifth the cost of what the state already said was economically feasible, it certainly ruled out that one.

There was the third criterion – that controls couldn't cause ‘‘substantial widespread and long-term adverse impacts.’’ The state said that wasn't the reason they couldn't be considered either, although the TCEQ staffers seemed to hedge a bit here, seemingly wanting to say that, really, they didn't want to cause themselves adverse impact by admitting that they had been wrong for over a decade about this stuff.

The proposed control cannot be ‘‘absurd, unenforceable, or impracticable.’’ Clearly, if the Europeans are doing it on their kilns, it's none of those either. It's quantifiable, and up and running in power plants, cement kilns and incinerators.

And it has to speed the attainment deadline by a year. No problem. SCR could do that if it was installed in a timely fashion.

So at the end of the state's presentation, former Dallas County Judge Margaret Keliher asked the TCEQ staffer exactly why SCR wasn't considered a possible pollution control measure since none of these criteria that had been presented seem to rule it out. And the TCEQ's staffer's response was…………………………………………………………………………………………………………………………………………………………………….

No, really, that was the response. She couldn't say. It was that embarrassing. Because the rejection of SCR by TCEQ isn't based on any of those criteria. It's based on a political decision that's been made that no new pollution controls will be sought on the kilns or any other major industrial polluter as long as Rick Perry is running for President. Or "just because."

How ridiculous is this? At this point the TCEQ is taking an even more regressive view of SCR controls than the cement industry itself. In June, Holcim Cement's Midlothian plant requested a permit from the state that would allow it to build either a Thermal Oxidizer or an SCR until for the control of VOC pollution. Being the free market fanatics the Perry Administration claims to be, doesn't the fact that one of the Midlothian cement plants is asking for a permit that includes the possibility of installing SCR mean it's automatically technologically and economically feasible? The market is never wrong, right? Are the folks at Holcim so enamored of kinky, off-the-wall green technology that they'll just include it in a permit for laughs? These guys are Swiss engineers. They have no sense of humor.

Denial of SCR as a viable control measure that could reduce smog pollution is making the TCEQ contort into sillier and sillier positions. It's making them deny the conclusions of their own almost-decade old report that said it was available to put in a kiln in 2005. It's making them deny the fact that SCR is up and running at over half a dozen kilns in Europe. It's forcing them to once again use the "Midlothian limestone is magically special" defense that has been used to forestall any progress in pollution control there over the last 25 years. The arguments used against SCR are exactly the same as were used against the adoption of less effective SNCR technology before it was mandated. In case you hadn't noticed, they're still making cement in Midlothian despite the burden of having to nominally control their air pollution.

The state wants to power through this anti-smog plan just like they did the last one in 2011. They don't want to have to make industry do anything. But at this point the denial of SCR as a control measure to be included in the next DFW anti-smog plan is so absurd, as is the justification for electrification of gas compressors, that it might be fodder in the next citizens lawsuit over a DFW anti-smog plan, which usually follows these things like mushrooms after a rainstorm.

Want to get involved in this fight and make it more difficult for the state to get away with doing nothing at all about DFW smog – again? Please consider attending our next DFW Clean Air Network meeting – THIS SUNDAY, AUGUST 17th, from 3:30 pm to 5:30 pm at the offices of the Texas Campaign for the Environment across from Lee Park in Dallas, 3303 Lee Pkwy, Suite #402 (214) 599-7840. Citizens are the only force that can make this plan better. Be there, or breathe bad air.

Ask the State and Holcim To Finally Give DFW “the Holy Grail” of Cement Pollution Control Technology

Swiss-based Holcim Cement is requesting a permit amendment to add new piece of pollution control equipment to its Midlothian cement plant, one of three cement plants that make the city the "Cement Capitol of Texas" and the largest concentration of cement manufacturing in the U.S. Good news, right? The problem is that the company is asking the state for the permit before deciding what kind of pollution control equipment to install.

Swiss-based Holcim Cement is requesting a permit amendment to add new piece of pollution control equipment to its Midlothian cement plant, one of three cement plants that make the city the "Cement Capitol of Texas" and the largest concentration of cement manufacturing in the U.S. Good news, right? The problem is that the company is asking the state for the permit before deciding what kind of pollution control equipment to install.

That's right. Holcim is asking the Texas Commission on Environmental Quality (TCEQ) to OK a permit that will result in a "major modification" of its Midlothian plant and could produce significant amounts of new pollution before it even decides what the major modification is going to be. Anywhere else in the country this might be a bit odd, but hey, it's Texas, where Rick Perry's TCEQ has a rubber stamp standing by for anything industry requests.

Holcim's permit request is being prompted by a problem complying with new federal regulations limiting a kind of pollution called Total Hydrocarbons, or THCs. These are also sometimes referred to as "Volatile Organic Compounds." Think Benzene, and other kinds of hazardous flammable gases. In its permit application Holcim says it needs to add new controls to reduce THC to levels and come under the new federal standard. Fair enough. The company then says that it's still trying to decide between two different types of controls and will make up its mind after getting the permit and seeing how well its choice works out on one of its two separate giant kilns. That's the bogus part.

But wait, there's more! The two technologies Holcim is considering installing in Midlothian are: 1) A Regenerative Thermal Oxidizer, or RTO, which is a fancy way of saying setting them on fire and flaring them off, and, 2) A Selective Catalytic Reduction unit, or SCR, which is a tower of treated metal honeycombs that pick up pollution as the plant exhaust passes through them. RTOs are already installed on American cement plants, including TXI's huge Midlothian kiln just a few miles down Highway 67 from Holcim. On the other hand, up to now full-scale commercial SCR units have only been installed on European cement plants and in fact, the Portland Cement Association has lobbied long and hard to keep them out of the US for fear of raising the pollution control bar too high for all of the country's cement plants.

That's because SCR is more expensive to build and maintain than most cement plant control devices. But for the money, you get the Holy Grail of cement plant pollution control technology.

Most of the European cement plants that have SCR units install them to remove another type of pollution from their stacks – Nitrogen Oxides (NOx). If that sounds familiar, it's because NOx is a major smog-forming pollutant, and DFW has so much of it that the region has never been in compliance with the Clean Air Act standard for smog. And you'll never guess which facilities are the single largest sources of NOx pollution in North Texas. Or maybe you will: the Midlothian cement plants. That's why Downwinders at Risk has made it a point to campaign to require all three Midlothian cement plants – Holcim, TXI and Ash Grove – to install SCR….since all the way back in 2001, when the first European units were deemed a success at a German cement plant. SCR can remove 80 to more than 90% of all NOx coming out of a cement kiln. The 6500 tons of NOx a year that the Midlothian cement plants are permitted to release could be reduced to 650 tons with the application of SCR.

Now, as it turns out, SCR units are great not only at capturing large amounts of NOx pollution, but all kinds of other industrial pollution coming out of cement plants as well. Like THCs – up to 70% or so, but also Particulate Matter, Metals, Greenhouse Gases, Carbon Monoxide, and Dioxins. It's what's called a multi-pollutant control device because it does such a good job of eliminating a wide variety of nasty stuff from smoke stacks. This is what makes it the state-of-the-art technology for communities hosting kilns. In contrast, RTOs are single-purpose pollution devices aimed just at hydrocarbon removal and aren't designed to remove other kinds of emissions.

So even though Holcim is considering operating SCR because of its hydrocarbon problem, it would have a massive impact on the plant's air pollution across the board. And if Holcim were to set the precedent, the clock would begin ticking on bringing SCR to the other two Midlothian cement plants as well. It would only be a matter of time.

The public comment period for telling the state whether to accept or reject Holcim's permit application ends this Friday, July 11th at 5 pm. (If you're interested in jumping through the hoops to fill out the online form for official comments, you can go here and use Permit Number 8996)

Downwinders is submitting detailed comments praising Holcim for considering SCR, but urging the TCEQ to reject this permit because it's too vague and doesn't commit the company to any partciular technology, including SCR. We've also been collecting letters form local officials and stare legislators that urge Holcim to definitively choose SCR.

Now we're asking you to help us bombard both the Texas Commission on Environmental Quality and Holcim's US headquarters in Dundee Michigan in the next 48 hours with the same message to show public support for the company to do the right thing while rejecting a placeholder permit that doesn't commit it to do that right thing.

We want a permit request from the company that says Holcim will definitely install SCR, becoming the first commercial application of this state-of-the-art technology in America.

Using our "Featured Citizen Action" link, you can send such a message to Austin and Michigan in a matter of seconds right now. All you have to do is click here and then send the e-mails. We guarantee there's no more important or easier thing you can do for clean air in North Texas this week than sending these e-mails to the TCEQ Commisisoners and Holcim Corporate leadership. Please help us get the cement plant pollution control technology DFW deserves. It will only take a matter of seconds for you to help us achieve a goal we've been working toward for 14 years. We can do this. But we need your help. Now. Thanks.