Alternate Fules

HEFTY! HEFTY! HEFTY! is TOXIC! TOXIC! TOXIC!

Anti-Litter Group “Keep America Beautiful” Teams-Up with Dow and Hefty to Burn Plastic Bags Full of Plastic Garbage in Cement Kilns

And They Want To Do It Here…

We’ve been warning you for a while that garbage burning was coming to North Texas one way or another.

What we didn’t anticipate was that “Keep America Beautiful” would bring it.

That’s right. The same group that gave you Oscar “Iron Eyes” Cody crying over litter is now prepared to make your own eyes water and sting from the air pollution it wants to encourage by burning municipal solid waste, especially “hard-to-recycle” plastics.

Touting bright orange “energy bags” as a quick and easy alternative to throwing those plastics away, a news release issued by the Keep America Beautiful folks, your friends at Dow Chemical, and Reynolds, the makers of “Hefty” trash bags, claims they’re “a convenient way to collect plastic materials that would otherwise end up in the landfill and offers a platform to promote positive behaviors to prevent this material from being wasted.”

What they don’t tout as much is their alternative to throwing these plastics into a landfill – throwing them into a furnace.

As long as cement kilns need a high-temperature flame to make their product, they have large energy costs. Typically, 30% or more of the costs of running a cement plant is in buying the flammable materials necessary to keep that flame lit.

History has taught us that cement kiln operators will burn anything, including the kitchen sink, if they think it will help reduce those high fuel costs.

History has taught us that cement kiln operators will burn anything, including the kitchen sink, if they think it will help reduce those high fuel costs.

Kiln flames in Texas used to be powered by natural gas exclusively. Then it was coal. Then it was hazardous waste and coal. Then industrial wastes. And now municipal solid wastes. In bright orange plastic bags.

Cement plants don’t have to pay for the wastes, now termed “fuel,” for regulatory loophole purposes. In fact, because it’s now a “fuel,” they often get the waste for free or even get paid to burn it. It becomes a new center of profit in the company besides making cement. Maybe even more important. In the 1990’s, there were plenty of rumors about how the TXI cement plant in Midlothian would burn a lot of hazardous waste they got paid a handsome fee to take, but not have much cement product to show for it.

While garbage burning cement kilns have been on the rise in the developing world, the practice hasn’t caught on in the U.S.

Dow’s and Keep America Beautiful’s friendly neighborhood “Energy bags” are a way to jump start it.

This is already happening in Omaha, where 8,500 homes have filled 13,000 “Hefty Energy Bags” since the program’s launch in October. That’s resulted in more than 13,000 pounds of plastics being burned in a near-by Ash Grove cement kiln. They’re so excited about burning plastics at Keep America Beautiful that they’re not only endorsing the practice, they want to bring it to a cement kiln near you.

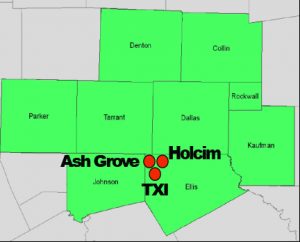

At a news conference to announce the offering of cash money grants to local communities who wanted to try the option, they unveiled a contiguous states map of the US where they’d like to see the “energy bag” concept implemented. The approximately 50 locations on the map identified by a red (not orange?) star are almost all sites adjacent to large cement plants – including Midlothian, immediately south of the Dallas and Tarrant Counties line, and home of the largest concentration of cement manufacturing in the nation.

Local candidates for eager participation in the project include TXI, the cement plant that burned hazardous waste by the thousands of tons from 1987 to 2008, Holcim, which has sought permits to burn carpet scraps and shingles, and Ash Grove, the same operator as the one burning Omaha’s plastic bags now.

BURNING PLASTIC IS BAD FOR PUBLIC HEALTH AND PUBLIC POLICY

1. It replaces real recycling with burning.

Once you have a hungry garbage burner, you have to keep feeding it with more and more garbage, decreasing the market for real recycling.

This is already happening with tires. There are good tire recycling programs that can’t stay afloat because local governments have promised the local cement kilns a certain volume every year.

2. It gives an incentive to the plastics industry keep to just making plastics that you can’t recycle.

Burning plastic garbage is like a relief valve on the growing piles of “hard to recycle” plastics that industry is producing. Just throw it in a bag and send it to the kiln. Out of sight, out of mind. There’s no question it reduces the percentage of plastics going to landfill…only to increase the percentage of plastic going into your lungs.

The real answer is to reduce and quit producing those “hard-to-recycle” plastics, not giving them a cheap way to get out of doing so.

3. Burning plastic produces lots of toxic air pollution – and all of DFW is downwind of Midlothian

Burning plastics produces toxic air pollution, a percentage of which escapes the smokestack and ends up in the air you breathe, the soil in your garden, and the food you eat and drink. Specifically, burning plastic creates lots of Dioxins and Furans – the same ingredients that made Agent Orange so toxic. The same poisons that made the State of Missouri evacuate the town of Times Beach in 1983.

Burning plastic also releases metals into the air, like cadmium and lead.

Other chemicals released while burning plastics include benzo(a)pyrene (BAP) and polyaromatic hydrocarbons (PAHs), which have both been shown to cause cancer. If plastic film or containers are contaminated with pesticides or other harmful substances, those will also be released into the air. If plastics are burned with other materials, whole new toxic chemicals may be created from the interaction of the different substances.

But wait! Don’t you want to divert more garbage from going to landfills?

Yes you do, but by eliminating, reducing and recycling the garbage – not taking a match to it.

Landfills are nasty things. They’re big and smelly and they leak. Sometimes they leak and contaminate ground and surface water. But these days you usually can trace the plume of those leaks and contain them before they get in drinking water.

On the other hand, once a piece of dioxin-contaminated soot is shot through a smokestack into the atmosphere, you have no idea where it’s going. You’re turning the whole sky into a landfill, full of solid and gaseous residues of refuse. What you didn’t want to drink, you’re now breathing. That’s the opposite of progress.

Taking a look at the Board of Directors for Keep America Beautiful, it’s no wonder they have a soft spot in their heart for large plastics manufacturers. They have not one, but two members from DOW, who, we are sure, thought this was a splendid idea.

Howard Ungerleider is Vice Chairman and Chief Financial Officer of Dow, and Greg Jozwiak is the Business President for the Elastomers and Electrical and Telecommunications businesses for the company. Prior to assuming his current role, he served as North America Commercial Vice President for the Packaging & Specialty Plastics business. Hmmmm.

But wait, there’s more! KAB has a board guaranteed to offend just about everyone. Not content with two Dow executives, it also has two Nestle Corporation members, a representative of Waste Management Inc., McDonalds, Keurig, Anheuser-Busch, and Phillip Morris – yes, that Phillip Morris.

“PEOPLE START POLLUTION. PEOPLE CAN STOP IT.”

Those are the words, spoken in a deep baritone by William “Cannon” Conrad, that ended that famous 1971 Keep America Beautiful commercial in honor of Earth Day. They ring as true now as then.

And so, people, we’re asking you to take action to discourage this kind of BAD IDEA from ever coming-up at a Keep America Beautiful board meeting again – send an email to their new Chair, Helen Lowman.

Ms. Lowman is a former FEMA and Peace Corps executive in the Obama Administration. She’s from Texas, worked at TCEQ, and graduated from Austin College…. So maybe messages from her fellow Texans will have more of an impact.

TAKE ACTION:

TELL KEEP AMERICA BEAUTIFUL’s NEW CHAIR YOU DON’T WANT TO BREATHE TOXIC AIR POLLUTION FORM BURNING PLASTICS

SEND AN EMAIL WITH JUST TWO CLICKS

And if you want to leave a public message for the group too, here’s the group’s FaceBook site.

Other citizens groups, including some national alliances and networks are gearing up to take on this latest proof that all wastes, no matter how toxic, roll downhill to cement kilns eventually.

Meanwhile, Downwinders is taking the lead and beginning the push back we hope buries this project in the bright orange trash heap of history. Join us in not just saying “No,” but “Hell No.” Send that email now and then find two other people that will do the same. Thanks.

Downwind in Switzerland: “Do you carry responsibly-sourced concrete?”

(Half of these people represent industry. Half are environmentalists. Can't tell which ones? That's a good thing.)

Should a bag of concrete be like an organic banana or a new chair made out of recycled wood and get "certified" as being responsibly-sourced, or "sustainable?" And if so, what's the criteria for making such a judgment, and who's making it?

Those are the complicated questions at the heart of a new worldwide initiative by the concrete/cement industry to come up with a way to sell its products in a more environmentally-friendly way.

After a couple of years of working on a scoring scheme, the mostly European-based intra-company group (LaFarge/Holcim, Heidelburg, CEMEX) charged with designing the system was ready to unveil it to the international environmental community for the first time in mid-July at a small meeting in Gland, Switzerland, headquarters of the International Union for the Conservation of Nature, whose staff facilitated the review process. IUCN had performed the same function for the aluminum industry when it went through a similar "green" self-examination.

Nine different environmental groups from at least seven different countries (Britain, Bulgaria, China, India, Lebanon, Switzerland) spent three days assessing and critiquing the industry's proposal – including the lone representative from the U.S., Downwinders at Risk's Jim Schermbeck. Participants not only met during the day, but ate together, and stayed in the same lone hotel in the small, outlying suburb of Geneva. Inside the meeting room, discussions were often frank, funny, and awkward. Outside, conversations ran the gamut, from architecture, to vacation trips, to Texas BBQ.

It's not a surprise that the concrete/cement business wants its relatively messy business to be seen through green-tinted glasses. Old timers will recall the burning of hazardous waste in Midlothian cement plants was relabeled "recycling" in the 1980's and 90's.

But this time around, the pressure is not necessarily to greenwash the transformation of a cement kiln into a waste incinerator, but to give an environmental patina to the final product, concrete, so that it can compete in the marketplace with building materials that already have their own green certification schemes up and running.

In other words, there appears to be new market pressure on the industry to "go green." Wood and Aluminum all now have their own systems for doing so. Concrete/Cement is lagging behind because it can't point to such a system. They want everyone from a construction site manager to a do-it-yourselfer to ask for "certified concrete" in the same way customers want wood that wasn't cut from a rainforest habitat, and aluminum made with Bauxite that wasn't mined at the expense of indigenous peoples.

Congratulations. Consumer demand for green products is so great that even the conservative cement/concrete industry feels the need to respond.

But that's also not news to North Texans. Certainly one reason Downwinders had a seat at the table in Switzerland was our pioneering Green Cement campaign of 2006-2011 which used government procurement policies to reward less polluting Midlothian cement kilns and punish the dirtier plants. That was the first time the marketplace for cement had been used toward greener ends in the US.

While that local effort looked exclusively at the differences in air pollution impacts from the Midlothian cement kilns, this new initiative starts at the limestone quarry, includes the aggregate industry (sand and gravel) goes through the cement kiln, and then continues all the way to the concrete batch plant and the bag of Sakrete at the store. It looks at impacts to water supply and quality, air quality, energy use, climate change, and local populations at each of these stops along the product cycle.

Much of the energy behind the initiative seems to come from a new generation of European industry representatives who've grown up with a different sensibility that takes green values for granted. More than one environmentalist noted a more open and questioning tone to the back and forth conversations. Whether this new attitude can be sustained and allowed to flow into real policy changes, is of course, the acid test of this first round, which must be finished for a pitch to the CEOs of the major industry players in December. Apparently the bosses are not entirely sold on the idea of needing such a certification at all, and, at times the whole idea had the air of being a kind of end-run around the Establishment by some Young Turks, albeit, corporately-backed.

And there are some very large challenges that could sabotage any good intentions, primarily, the continued reliance on burning wastes for the substantial fuel needs of a cement kiln. As much as kilns have modernized, making cement still involves cooking rock at very high temperatures provided by a very hot, continuous flame. Something has to fuel that flame day after day, year after year. Just buying the fuel for that flame represents as much as 60% of the operating costs of a cement plant.

This is why companies are always looking for ways to cut those energy costs: by turning themselves into incinerators and charging generators to burn their toxic wastes, by getting subsidies from government to burn wastes like tires, by getting refuse from other industries which would otherwise have to pay to have them hauled away. In terms of large PR problems, none loom larger than the inherent one that goes with the introduction of burning wastes in the local kiln. That's how Downwinders got our start.

But because of the volume of fuel needed as well as the required high temperatures, there are only so many kinds of things a kiln can practically burn. Midlothian kilns began by burning natural gas. If you're only looking at the end result of the flame, and not how the gas got here, it's still probably the cleanest source of fuel. Then there's coal, which is a no-go fuel in 2016 for all kinds of reasons. After that you get to wastes. Even if it doesn't have a permit to burn "hazardous" wastes, a kiln still can burn things like carpet pieces, plastics, shingles, and car "fluff." These are all materials that can release toxic air pollution when burned. Finally there's biomass – wood refuse, agricultural waste, or fuel crops themselves like sawgrass. Originally supported universally by environmentalists, these choices now have climate consequences that make them less desirable.

These are not easy choices for industry….or environmentalists. Schermbeck made the offer to industry to sit down and work on an agreed "hierarchy" of wastes that would establish minimum high BTU value and low toxicity levels, as the group had done over a decade ago with TXI in a private mediation process that never panned out, but showed vast differences in fuel characteristics. At last word, the offer was being mulled over by industry along with all the other suggestions made by environmentalists. By October we should know how first round of assessment has changed the scheme – or not. Then another round of feedback from the environmental community, and a final decision by the end of the year.

At stake is the potential to connect environmental progress and profit-making within one of the most environmentally-disruptive industries around. To establish performance floors, raise best practices, set new precedents. There are large risks and opportunities for both sides.

Besides being close to the corporate headquarters of most of the major companies invovled, and home of the IUCN, Switizerland seemed the appropriate place for this first-time gathering for another reason. At the end, everyone arrived at as if on the edge of a metaphorical mountain precipice with a sizable, but not insurmountable gap separating where the industry is now, from where it needed to be. Whether that gap can be bridged any time soon remains to be seen. But the meeting in Gland was a good keystone to put in place for any future span designed for the job.

Your’re Downwind of Lots of Burning Trucks

A funny thing happened to Dallas Morning News automobile columnist Terry Box while he was out test driving a new Dodge pick-up truck – it self-immolated and burned to ashes on the side of the road. As he writes about it, his experience is both funny and terrifying. But something he noted in how cars and trucks are made these days caught our eye:

A funny thing happened to Dallas Morning News automobile columnist Terry Box while he was out test driving a new Dodge pick-up truck – it self-immolated and burned to ashes on the side of the road. As he writes about it, his experience is both funny and terrifying. But something he noted in how cars and trucks are made these days caught our eye:

"Open the hood of your late-model car or truck, and you’ll see a half-acre of plastic — actual engine pieces like valve covers, caps and containers for various liquids.

Thirty years ago, most of the pieces under the hood were metal and resistant to fire.

A fire in a modern vehicle burns fast and furiously. What’s intact for the moment can be gone or enveloped in toxic smoke in a matter of seconds."

Yep. When we've described the lovely new cement additive called ASR – Auto Shredder Residue – we've often talked about all the vinyl seats, dashboard and switches that get stipped out of a car and shredded, then thrown into a cement kiln. We really haven't talked about all the plastic in the engine compartment that would also be included in this new "fuel" that TXI has already been permitted to burn at its Midlothian cement plant.

As more and more of every car is made of "soft materials" – that is, not metal – more and more of it becomes fodder for cement kilns. This is material that could be recycled but isn't, and as long as it's cheaper just to burn it, there won't be amrket for recycling it.

Here's the thing, burning plastic creates bad kinds of pollution, including the creation of Dioxin, one of the most potent posions ever discovered by science. The same "toxic smoke" Terry Box saw pouring off of his burning Ram pick-up is created when you throw the same plastic parts into a cement kiln. The cement industry would like you to think that all of that is taken care of by the polluton control measures installed at the kilns, but it's not. There's no real time Dioxin montoring, much less any kind of monitoring for the host of other exotic fumes coming off burning plastic of various kinds. They barely even know what or how to test for such pollutants, but that doesn't keep the cement industry from marketing its kilns as "Long, Hot, and Good for America"™

If you're an old-timer, you might remember an earlier episode or two that occurred when the cement industry, including TXI, assured everyone that it could burn hazardous waste and make it completely disappear into water vapor. Remind us, how did that turn out?

Scientists: Classify Plastic As Hazardous Waste

We missed this the first time around, so we're glad that "Living on Earth" caught it again. A group of scientists, including marine biologist Chelsea Rochman, recently signed an article in the magazine Nature that called for classifying plastic as a hazardous waste.

We missed this the first time around, so we're glad that "Living on Earth" caught it again. A group of scientists, including marine biologist Chelsea Rochman, recently signed an article in the magazine Nature that called for classifying plastic as a hazardous waste.

What's the rationale? It turns out to be pretty solid and based on current regulations. As Rochman described it,

Waste is basically separated into two categories, those that are non-hazardous like grass clippings, and those that are considered a hazard, which are often based upon this long list of priority pollutants, or substances that the government deems are hazardous to organisms. And we found that plastics are associated with 78 percent of these priority pollutants listed by the US EPA and 61 percent listed by the European Union, either as a chemical ingredient of the plastic itself or when the plastic ends up in the aquatic environment; they absorb these contaminants from the water. And so from that perspective we thought maybe plastic as a waste product should also be considered as a hazardous substance.

Rochman cites styrene in Styrofoam as an example of a well-known pollutant that's incorproated into plastic. Another is vinyl chloride that's used to make PVC.

Plastics' threat to marine life has been well-documented, but it's also a threat to those living downwind of places that burn plastic wastes – like an increasing number of cement plants, including TXI's huge Midlothian Kiln #5. Besides being assaulted by the leftovers of the ingredients in the original plastic, downwind neighbors are also subjected to entirely new pollutants that are made ONLY when plastics are burned. The most notorious of these is Dioxin, one of the most potent poisons ever tested. Dioxin is what made Agent Orange so toxic to Vietnamese and veterans alike. It's why Times Beach Missouri is a Superfund Site. And it's what's released every time plastics are burned.

Incineration of plastics is dramatically increasing despite producing this kind of pollution. Classifying this waste as "hazardous" might be the only way to limit their use as "fuel" in cement kilns that weren't built to be garbage incinerators.

Another Chapter of Cement Kilns As Garbage Incinerators

One of the reasons it's so disheartening to have EPA rollback the deadline for new cement plant air toxics standards and gut the PM pollution provision of those standards is because of the large and fundamental shift in what's being burned is taking place within the industry. Downwinders across the country need the protection of these new rules as soon as possible, as everything, including the kitchen sink, is being thrown into kilns.

One of the reasons it's so disheartening to have EPA rollback the deadline for new cement plant air toxics standards and gut the PM pollution provision of those standards is because of the large and fundamental shift in what's being burned is taking place within the industry. Downwinders across the country need the protection of these new rules as soon as possible, as everything, including the kitchen sink, is being thrown into kilns.

There's a determined effort underway nationwide for cement plants to secure new permits or permit "amendments" or "modifications" to burn increasing amounts of municipal and industrial garbage, including lots and lots of plastics. With new regulation of hazardous waste burning in the US taking some of the fun and profit away from that practice, the trend is now headed toward burning all kinds of "solid waste" including hard to recycle bits of municipal and industrial garbage like plastics and car "fluff" – all the non-steel parts of a car or truck, including dashboard, electronics, interiors, brake linings, etc.

Locally, TXI's 2011 permit amendment – given without public notice or opportunity for comment – is the worst example of this national trend, although Holcim and Ash Grove are also burning tires, used oils, and other kinds of industrial waste already.

Now word comes of the CEMEX plant in Louisville also making plans to burn plastics and other kinds of garbage, but

"…industrial pollution has been an issue in southwest Louisville for decades. The plant is near the coal-fired Mill Creek power plant, and residents have long complained about dust and soot from both.

Denise Allgood, vice chairwoman of the Valley Village Homeowners Association, said she was not familiar with the proposal and said any change involving air pollution is likely to be sensitive.

The (pollution) that’s coming out of that place now is of great concern,” she said. “We’ve been told by the powers that be that’s it’s better than it has ever been, but I would hope that whatever (CEMEX) is considering, they are also considering the health and welfare of the people in this area.”

What could make the problem wortse? Burning plastics that release exotic new chemicals that can hitch a ride on all that old soot and dust. We're entering a whole new era of contamination by incineration once plastics-burning becomes widespread in the nation's cement kilns. That's a big reason why we need the added protection of the EPA rules.

German Cement Plants Now Mostly Waste Burners

The cement industry calls it "alternative fuel" or "co-generation," but it's really just waste burning. This was true during the 1980's and 90's when the cement industry began converting kilns to large hazardous waste incinerators, and it's true now that the industry is trying to turn kilns into giant garbage incinerators. In one permit request after another across the country, cement plants are adding not just used tires and oil, but plastics wastes, automobile interiors and anything else they can get in bulk to the list of "fuels" they can burn. Locally, TXI's 2011 "permit amendment" allows the Midlothian kiln to burn a long lists of industrial wastes. To see where this leads, look no further than Germany, where fully 61% of all fuel consumed in that nation's cement kilns in 2011 was provided by plastics, used tires, and used oils. It's worth noting that European emissions requirements are usually stricter than EPA's, but the figure is still alarming since it was only about 30% in 2000.

The cement industry calls it "alternative fuel" or "co-generation," but it's really just waste burning. This was true during the 1980's and 90's when the cement industry began converting kilns to large hazardous waste incinerators, and it's true now that the industry is trying to turn kilns into giant garbage incinerators. In one permit request after another across the country, cement plants are adding not just used tires and oil, but plastics wastes, automobile interiors and anything else they can get in bulk to the list of "fuels" they can burn. Locally, TXI's 2011 "permit amendment" allows the Midlothian kiln to burn a long lists of industrial wastes. To see where this leads, look no further than Germany, where fully 61% of all fuel consumed in that nation's cement kilns in 2011 was provided by plastics, used tires, and used oils. It's worth noting that European emissions requirements are usually stricter than EPA's, but the figure is still alarming since it was only about 30% in 2000.

Another “Alternative Fuel” Fire at a U.S. Cement Plant

Following a warehouse of industrail waste that spontaneously combusted at a South Carolina cement plant last month come news from Morga n, Utah that a semi and part of the "auxilary fuel" builing at Holcim's Devil's Slide cement plant caught fire while waste was being pumped from the truck. No injuries were reported. Expect more of these kinds of accidents as mixed industrial garbage is funneled into cement plants as "fuel.".

n, Utah that a semi and part of the "auxilary fuel" builing at Holcim's Devil's Slide cement plant caught fire while waste was being pumped from the truck. No injuries were reported. Expect more of these kinds of accidents as mixed industrial garbage is funneled into cement plants as "fuel.".

First they Come for the Peanut Shells

Here's a story from Florida about the Brooksville Cemex cement plant's new permit that displays the quintessential spin from the cement industry about their transformation into garbage burners. 1)The headline uses the preferred industry term of "alternative fuels" instead of garbage. 2) It leads with all the feel-good fuzzy bio-garbage like peanut shells and wood chips. Only further down do they let you see the rest of the list – "including plastics, carpet, roofing materials and wood treated with creosote. Included, too, are so-called engineered fuels such as cleanup debris from natural disasters, processed municipal solid waste, dried and sanitized sewage bio-solids, noninfectious hospital materials, expired pharmaceuticals and confiscated narcotics." 3) It makes sure you know that this new garbage burning will shrink the plant’s carbon footprint and lower emissions of toxic chemicals like Mercury – but the plant will not be amending its operating permit to reflect those proposed decreases. 4) for all the talk of "alternative fuels," the plant is mainly still burning coal and tires, both of which it's been burning for a long time. The largest expense of running a cement plant is fuel costs. The industry is always finding a way to cut those costs. In the 1980's and 90's it tried turning cement kilns into hazardous waste incinerators by getting paid by polluters to burn their crap for less money than the pros. That met with quite a bit of public resistance and new regulations that made it harder to keep doing that. So now the industry is pivoting toward a laundry list of "non-hazardous" wastes – municipal garbage, sewage, medical waste, plastics, car interiors – garbage. Except that anyone who's ever studied the the history of American garbage incineration – and there's quite a history – knows there's nothing non-hazardous about the practice. Just because a waste isn't classified by EPA as a "hazardous" waste coming in the front door doesn't mean it doesn't emit hazardous air pollution when it's burned or carted off as ash out the back door. And even thought there's a lot of boasting about emission decreases, the industry isn't backing up that talk with real cuts in their permits. Places like Midlothian, home of three huge cement plants, and a concentration of cement manufacturing unmatched anywhere else in the US, are looked upon as nothing but large "landfills in the sky" to both waste producers and the cement plant operators themselves. TXI's Midlothian plant, directly south and upwind of DFW, just received a new permit "amendment" last June that allows them to burn the same kind of long list of garbage as the Florida kiln. They got this without any public notice or hearing or anything. None required as long as TXI promises, cross their heart, that the emissions won't increase above what they are now. And if they do? We won't even be able to know for sure until a test burn that will occur after they start burning garbage – they can wait up to a year to do the testing. This is why public participation is an over-arching issue in Texas now.Without it, there are no checks and balances. Only more experiments taking place in your lungs.

Enviro Fuel Cubes! Now with More Dioxins and Metals!!

Word comes that Lehigh's Glens Falls New York cement plant is applying for a another version of a "Landfill in the Sky" permit that would allow them to burn International Paper's"Enviro Fuel Cubes" made-up of all kinds of wood and paper waste. Lehigh says the cubes reduce Sulfur Dioxide pollution. So do Scrubbers. On the other hand, the cubes also produce "minor increases" in dioxins, chromium, lead, and nickel. There is no safe level of exposure to minor increases in dioxin or lead. A letter to the N.Y. state environmental agency from 27 groups also points out that burning this kind of waste discourages the real recycling and in-house reduction of it. As always, cement kilns are acting as cheap garbage disposals for waste from other industries

New EPA Rules for Solid Waste Incineration at Kilns Still Suck

Among the many faux EPA outrages Big Business and House Republicans have fostered upon us, you may remember the meme that the feds were going to put thousands of hospitals and school boilers out of business with super strict new emission rules. In fact, the facilities most affected by the rules weren’t schools or hospitals. They were on-site chemical incinerators and boilers and of course, cement kilns. However, the pile of manure that was churned out enveloped the Agency and, as with the new ozone standards, made it retreat and reconsider the originally-proposed rules. Newly reconstituted, the Commercial and Industrial Solid Waste Incineration rules (CISWI) were dumped by the Administration last Friday at closing time like a late-night gangland victim at a hospital emergency room. After review, it’s easy to understand why. The rules did not go far enough for industry, which would find any regulations onerous. And in an attempt to win the business community favor, the administration gave away strict standards for particulate matter, dioxin, and toxic heavy metals like lead and cadmium. Nothing was done to narrow the broad definitions of “nonhazardous solid waste” that allows for the burning of just about everything is it gets the right exemptions, including tires, plastics garbage, car interiors, and creosote-treated wood. This is where the entire industry is headed – the grey area of these nonhazardous solid wastes – as exemplified by TXI’s “landfill in the sky” permit recently awarded by TCEQ to the company without any public notice or opportunity for comment. And for the time being, this administrations seems happy to allow it.